Rubber Strip With Full Options

100% customer satisfaction has quickly established us as a world-class, diverse and progressive organization.

Rubber Extrusion

The quality of the rubber sealing strip made by the rubber extrusion process is better. okin is a professional rubber strip manufacturer. Rubber extrusion seal strips have a wide range of applications. Changing the extrusion to ensure that extruded rubber seals with various cross-sectional shapes. And most importantly, there is no length limit for the rubber extrusion seal. Today, rubber extrusion is very popular in the market.

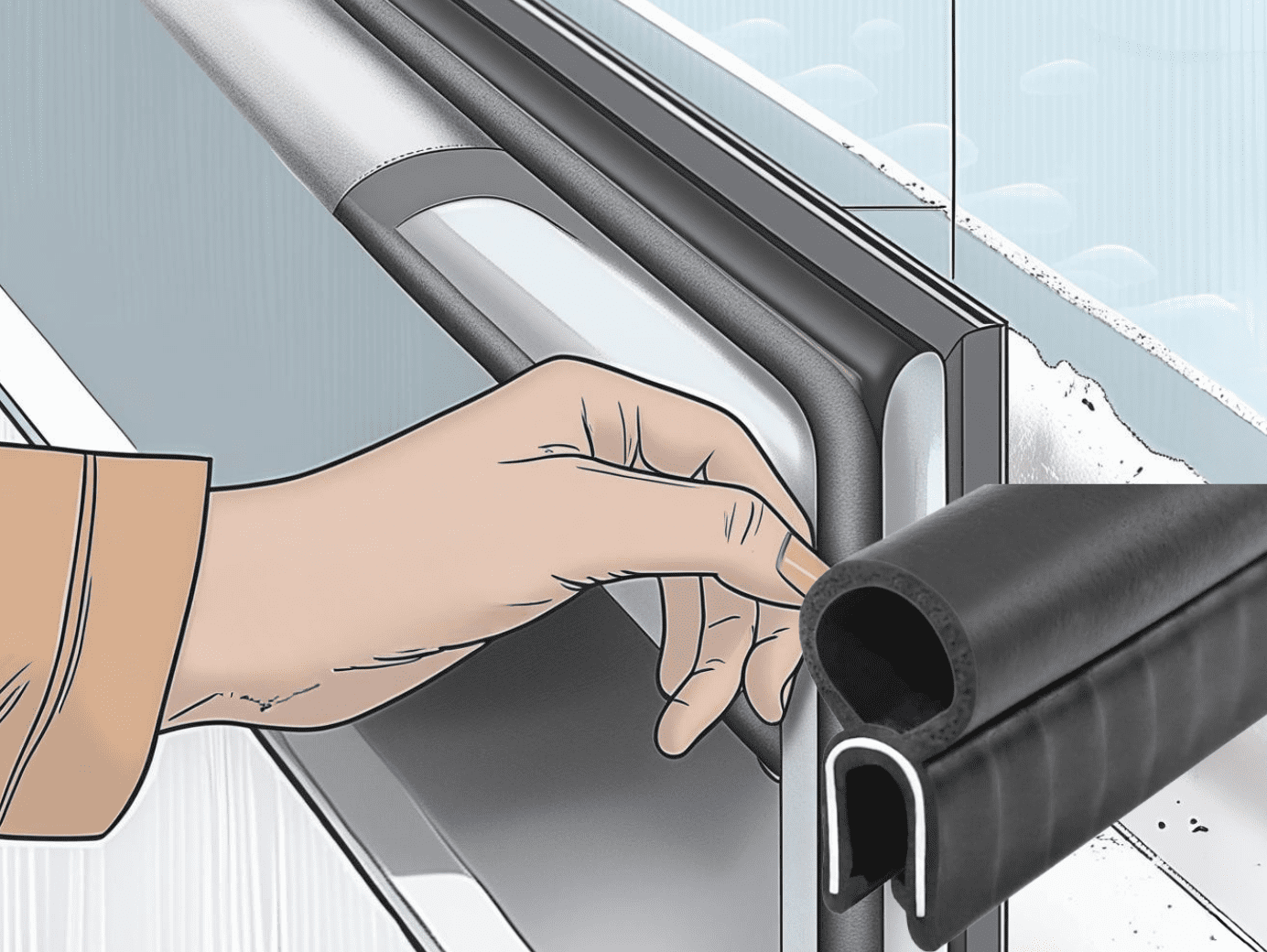

Rubber Co-Extrusion

The extruded rubber seal strip is durable and easy to install. Because the rubber co-extruded profile is mainly composed of EPDM rubber foam, it is dense and contains unique metal clamps and tongue-shaped buckles. okin is an excellent rubber extrusion supplier. When looking for extruded rubber seal service, you must find a professional.

Sponge Extrusion

The raw material of the sponge extruded sealing strip is EPDM rubber, which is a synthetic rubber. The primary ingredient is ethylene. Its main feature is that it has a low density and high filling and is resistant to aging, corrosion, water vapor, and superheated water. Nowadays, sponge seals have advantages that cannot be ignored. It has good toughness and softness. It is very light and will not add any weight to the transportation of sponge seals.

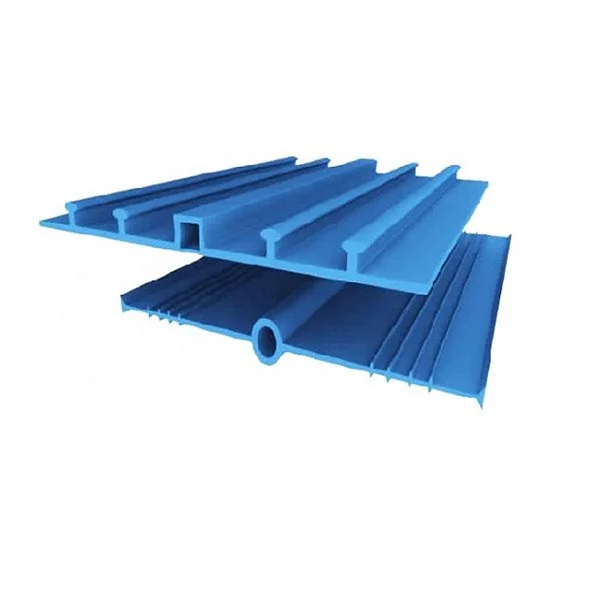

Plastic Extrusion

A plastic seal strip is a straightforward product that is used daily. For example, some door and window sealing strips, decorative sealing strips on cabinets, etc., are all PVC strips. During production, a plastic extruder produces the plastic sealing strip. The plastic sealing strip is resistant to corrosion, aging, and high and low temperatures. This environmentally friendly product has good anti-seepage, anti-leakage, and water-proof effects. okin rubber strips supplier provides you with great products.

OKIN is a manufacturer specializing in the production of rubber sealing profiles and customized solutions for sealing components.

Our company specializes in the development and production of high-performance plastic extrusion profiles, foam seals, and injection-molded seals.

Our main products include extrusion rubber sealing profiles, co-extrusion rubber sealing profiles,foam sealing strips, EPDM foam sealing strips, rubber edge trims, rubber damping parts, and waterproof materials.Our company specializes in costom rubber parts to meet the diverse needs of our clients.

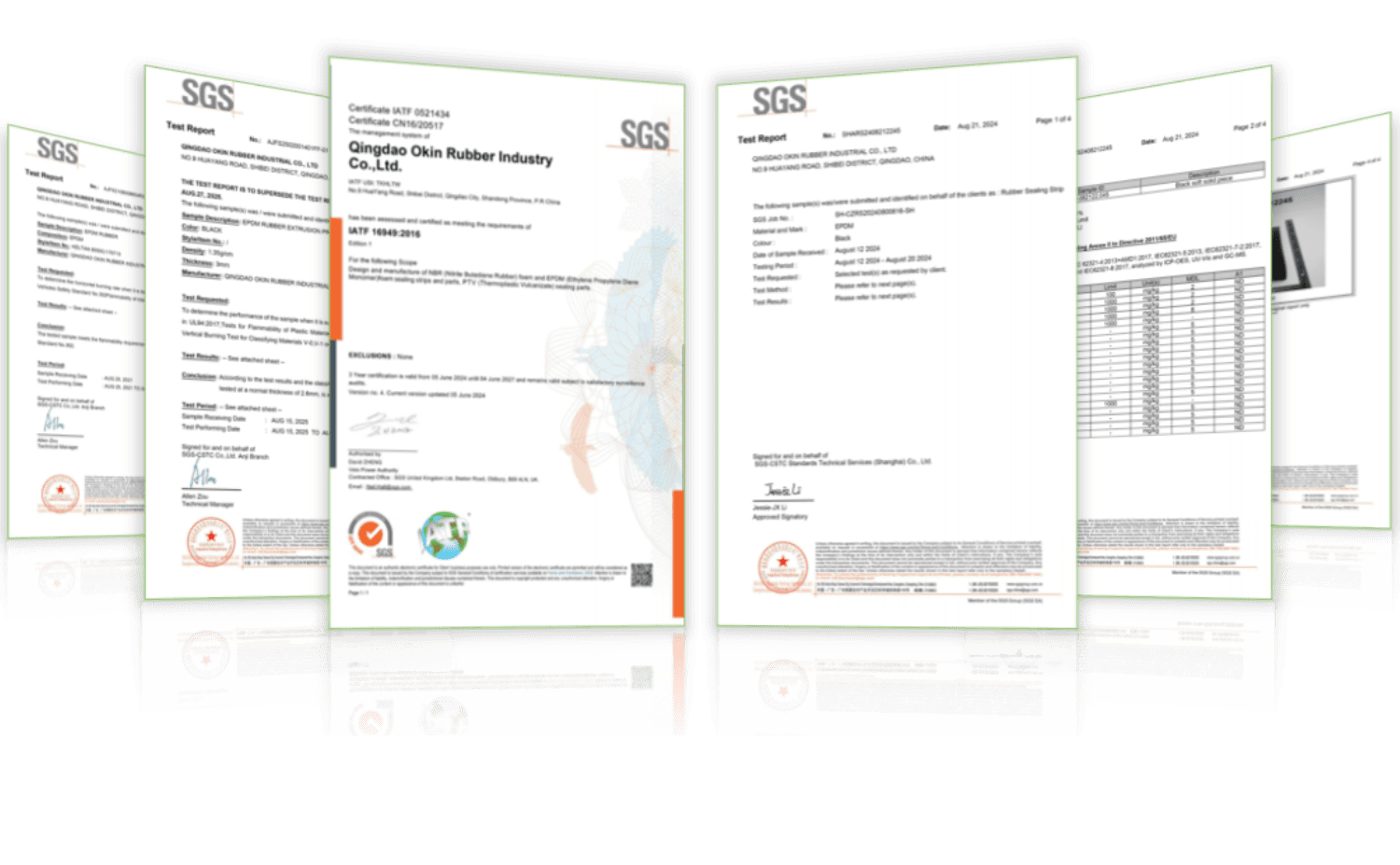

With advanced extrusion and molding technology, strict quality control, and competitive pricing, OKIN has become a trusted supplier for global industrial buyers. Whether you are a door and window installer, an automotive parts supplier, or a wholesale distributor of sealing profiles, OKIN offers you superior quality and durability.

20+ Years Of sealing products manufacturing expertise

Since our founding in 2005, Okin has been dedicated to supplying high-quality rubber extrusions profiles and plastic sealing strips to various industries. Including automotive seals, door and window seals, waterstops, marine hatch seals, container seals, refrigerator seals, waterproof rubber hoses and other rubber sealing products.

Wide Applications of Rubber Sealing Strip

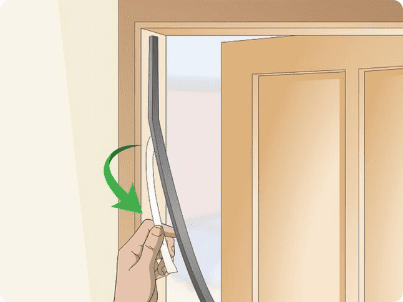

Window Seal & Door Seal Strip

A sealing strip is necessary for sound insulation, wind protection, or dust and insect protection. Whether it is door seal strips or window sealing, they are made of durable rubber or PVC. It can help our customers solve problems quickly.

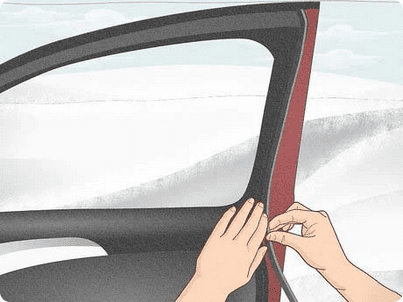

Car Window Seal & Car Door Seal

A car door rubber seal can be soundproof, leak-proof, and weatherproof, improving driving safety. A durable car window seal provides high protection for your car.

Seal Strip For Rail Vehicle

A marine weather strip with good aging resistance is critical. Seals are rarely replaced frequently. Good oxidation resistance helps to improve the service life of the sealing strip. Even after long-term use, it can ensure a good use effect.

Why Choose Us

As a China rubber extrusion company, we aim to make customers 100% satisfied. It has allowed us to grow from a one-product company into a progressive organization. And we have achieved world-class, high-quality rubber seal strips for various fields.