Custom Rubber Extrusion & Composite Sealing Strip

IATF 16949 Certified Manufacturer | 100% Virgin Rubber Material | Factory-Direct OEM Services

Solid Rubber Sealing Strip

Engineered from 100% virgin EPDM, NBR, and Silicone. This solid profile offers precise tolerance control and superior weather resistance, ensuring long-term sealing for automotive windows, heavy machinery doors, and industrial enclosures.

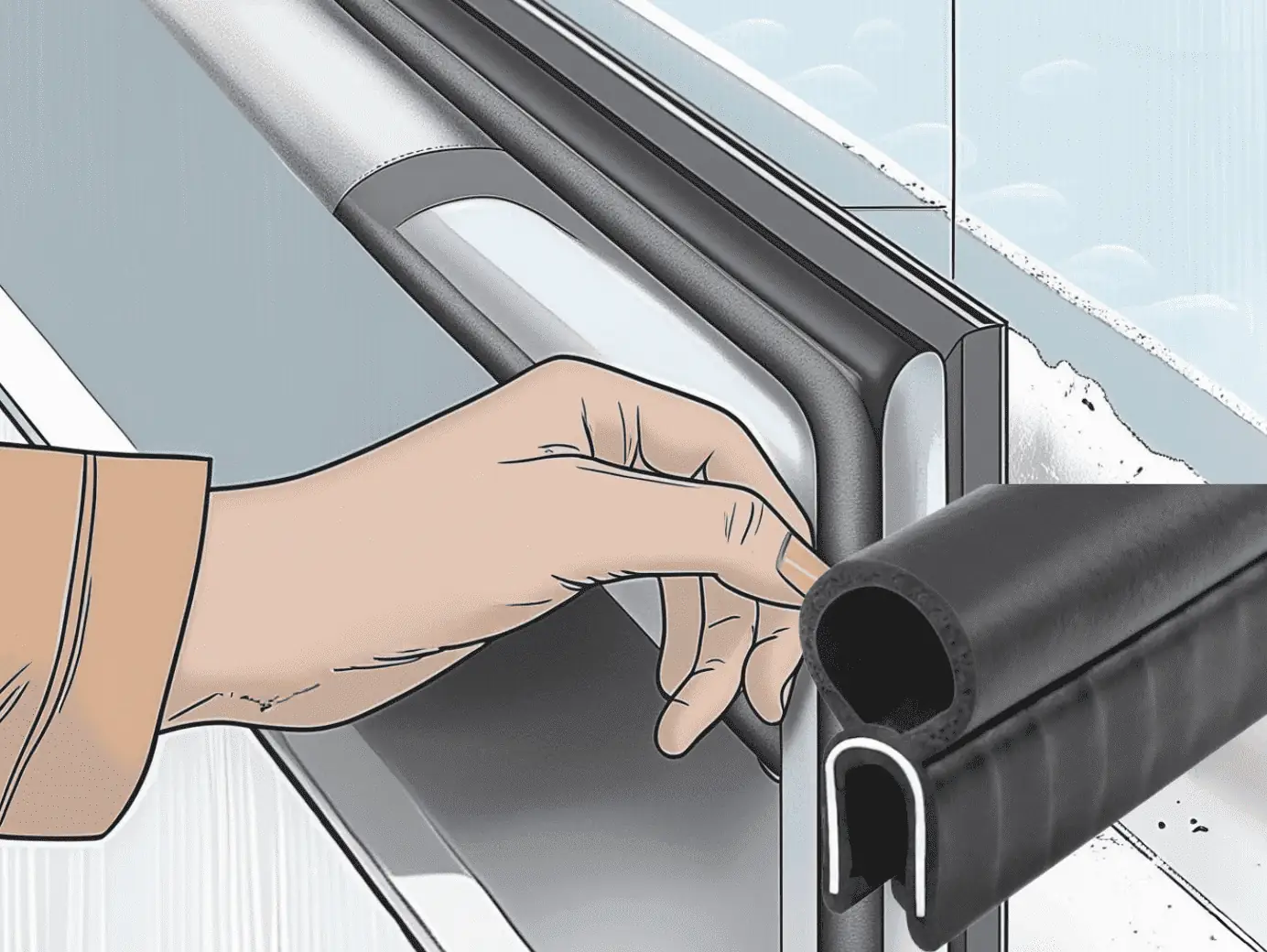

Co-Extruded Rubber Seal

Integrating solid rubber, sponge bulb, and steel core into one robust profile. This composite seal provides powerful clamping force and watertight closure, specifically designed for heavy machinery, shipping containers, and vehicle doors.

Sponge & Foam Weatherstrip

Featuring closed-cell structure and ultra-low compression set for rapid shape recovery. This soft rubber strip delivers excellent water-tightness for electrical cabinets, hatches, and HVAC systems, adapting perfectly to uneven gaps.

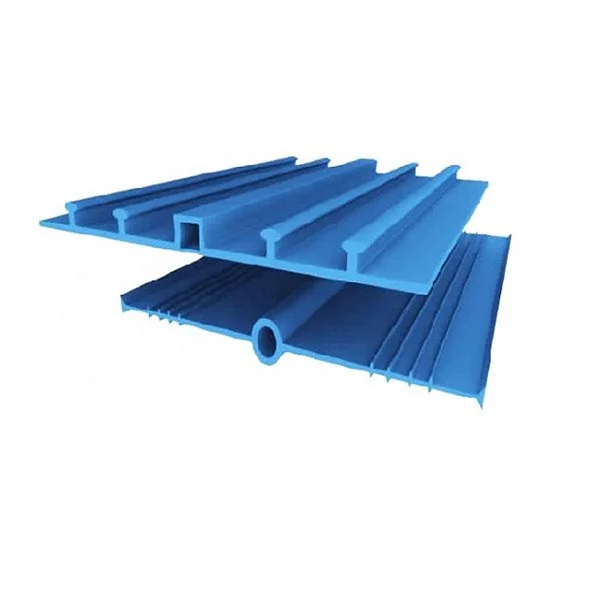

Plastic Extrusion Profile

Custom TPE, TPV, and PVC extrusion featuring precise color matching and full RoHS compliance. Ideal for architectural glazing, furniture edging, and shower doors, combining the flexibility of rubber with the lightweight durability of plastic.

Backed by IATF 16949 certified processes, OKIN specializes in engineering high-performance custom rubber parts. Our capabilities span precision EPDM co-extrusions, closed-cell sponge profiles, and complex injection-molded components. Using 100% virgin materials and advanced microwave vulcanization, we ensure every product delivers superior weather resistance and dimensional stability.

From rapid prototyping to mass production, we provide factory-direct efficiency for global OEMs. Whether you need sealing systems for automotive assembly, heavy machinery, or architectural glazing, our rigorous quality assurance and reliable supply chain management ensure your exact specifications are met on time, every time.

20+ Years Manufacturing Custom Rubber Extrusions & Molded Parts

Since 2005, OKIN has served clients in over 50 countries, evolving from a local manufacturer to a global OEM partner. We leverage an extensive database of existing molds—covering marine, container, and infrastructure sectors—to significantly reduce your tooling costs and lead times. By combining deep industry expertise with rigorous quality control, we deliver reliable, zero-defect sealing solutions for your most demanding applications.

Rubber Sealing Strips: Construction, Automotive & Railway

Engineered for versatility, our rubber sealing strips deliver superior weatherproofing and shock absorption. From automotive edge trims and marine container seals to heavy-duty industrial profiles, we provide custom sealing solutions tailored to your specific operational environment.

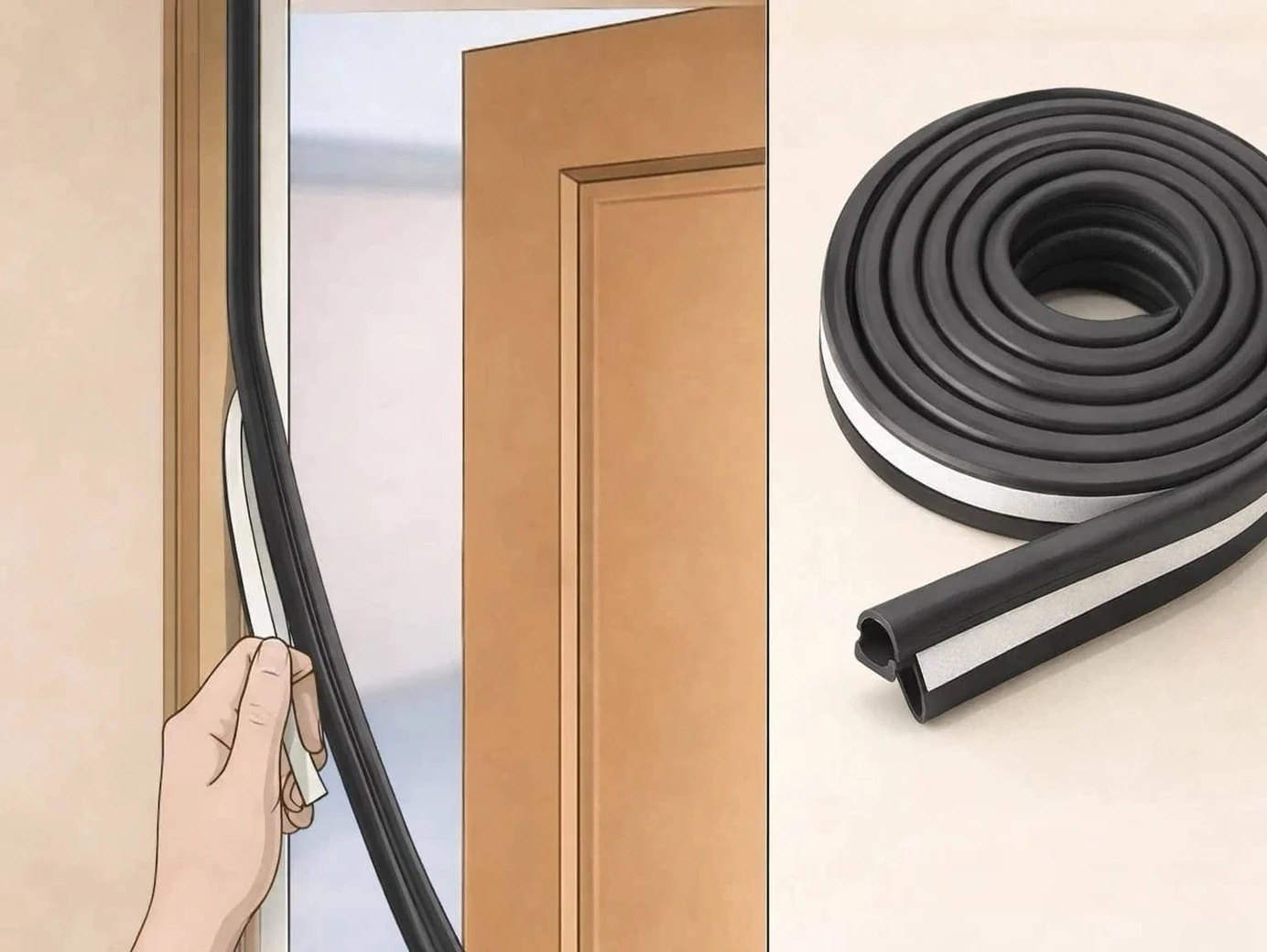

Commercial Window and Door Seals

Engineered from premium EPDM and Silicone, these profiles deliver superior thermal insulation and weatherproofing. They effectively block water infiltration and air leakage, ensuring long-term energy efficiency for residential and commercial high-rises.

Automotive Weatherstripping & Seals

Manufactured to strict OEM standards, our automotive seals provide exceptional shock absorption and acoustic isolation. Designed for doors, windows, and trunks, they ensure a secure, leak-proof fit that enhances driving safety and comfort.

Railway and Mass Transit Profiles

Heavy-duty profiles featuring advanced flame retardancy (meeting EN45545/UL94 standards). Built to withstand high vibrations and harsh environments, extending the service life of train doors and windows while minimizing maintenance frequency.

Why Choose OKIN Seal

As a premier manufacturer of custom rubber extrusions, OKIN Seal has evolved into a global industry leader. We are dedicated to delivering world-class sealing performance, engineering precision, and reliable supply chain solutions for automotive and industrial partners worldwide.