In global B2B sealing markets, demand for rubber seal strips continues to climb. From building windows and doors to automotive components, industrial machinery, and aerospace applications, the right cross‑section profile dramatically boosts sealing performance and lifespan. This guide covers 12 popular shapes, dives into material properties, selection criteria, industry trends, and marketing insights—empowering buyers and engineers to make informed decisions quickly.

Material Comparison

EPDM vs. Silicone vs. NBR

- EPDM: Excellent weather, UV resistance—ideal for outdoor windows & doors.

- Silicone: Ultra‑wide temperature range (–65 °C to +250 °C), chemical resistant—perfect for food, pharma, aerospace.

- NBR: Oil and abrasion resistant—suited for hydraulic systems and engine compartments.

Selection Guide

- Temperature Range: Below –40 °C or above +150 °C → choose Silicone.

- Chemical Exposure: Oils or fuels → NBR; acids/alkalis or food contact → EPDM or FDA‑grade Silicone.

- Pressure & Deformation: High‑pressure hydraulics → T‑ or V‑profile with NBR/PU blend.

- Installation Method: Self‑adhesive → D‑ or P‑profiles with adhesive backing; mechanical slotting → U‑ or H‑profiles.

- Durability Needs: Outdoor long‑term → EPDM U‑ or L‑profiles; dynamic indoor seals → P‑ or Bulb‑profiles.

Shape Groups Detailed

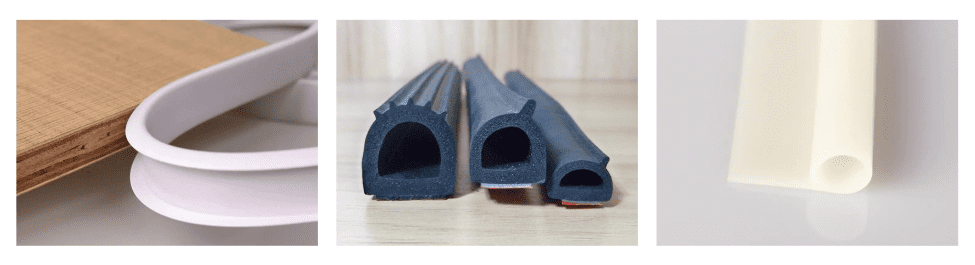

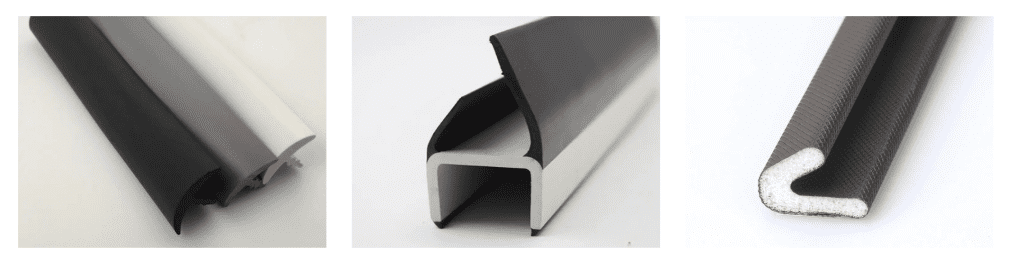

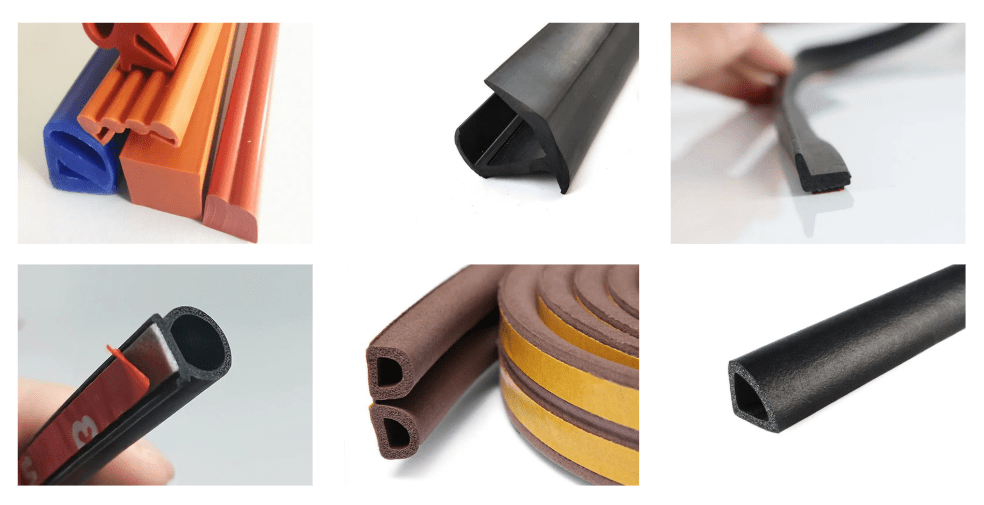

A. Window, Door & Automotive Seals

| Shape | Common Materials | Quick Tip |

| U‑Profile | EPDM, PVC | Embed steel core for wind‑load resistance |

| D‑Profile | Sponge EPDM + adhesive | DIY‑friendly, replaces brush seals |

| P‑Profile | EPDM, Silicone | FDA‑grade Silicone for refrigerated display cases |

B. Industrial & Engineering Seals

| Shape | Application | Shore Hardness |

| T‑Profile | Hydraulic cylinders, valves | 70–90 Shore A |

| H‑Profile | Aerospace doors, industrial ovens | 60–80 Shore A |

| V‑Profile | Machine guards, building joints | 50–70 Shore A |

C. Special & Multi‑Function Seals

| Shape | Key Feature | Example Use |

| E‑Profile | Sound‑insulating, shockproof | High‑voltage cabinet doors |

| J‑Profile | Ozone‑resistant, flexible | Marine hatch seals |

| L‑Profile | Wear‑resistant, impact‑resistant | Container door frames |

| Oval | Chemical‑resistant, UV‑stable | Chemical piping interfaces |

| Bulb & Double Bulb | High rebound, waterproof | Automotive window edges |

| Triangular/Trapezoid | Stretch‑resistant, insulating | Aerospace composite joints |

About OKIN ®

OKIN ® operates 21 advanced extrusion lines—including 6 co‑extrusion and 3 foam lines—specializing in custom rubber extrusion profiles and sealing solutions. Exported across Southeast Asia, Europe, the Middle East, and North America, our products serve leading clients in automotive, construction, chemical, and aerospace industries.

Empower your next project with OKIN’s industry‑leading seal strip expertise!