Introduction

Self‑adhesive rubber seal strips have transformed how professionals and DIYers approach sealing tasks. Gone are the days of nails, screws, and complex fasteners—today’s adhesive weatherstrips install in seconds, require no special tools, and deliver industrial‑grade performance. From preventing drafts in home windows to ensuring watertight integrity in marine hatches and automotive doors, these versatile strips provide reliable air‑, water‑, dust‑, and noise‑blocking capabilities. In this guide, we explore the science behind adhesive seal strips, the key selection criteria, top profiles, real‑world applications, and best practices for installation.

How Self‑Adhesive Seal Strips Work

- Profile Core: Made from EPDM rubber, neoprene, silicone, or closed‑cell foam. Provides the compressible cushion that fills gaps.

- Adhesive Layer: High‑bond acrylic or rubber‑based tape affixed to the back of the profile. Engineered for instant grab and long‑term adhesion.

- Protective Liner: Removable film that preserves tack until installation.

When pressed onto a clean substrate, the adhesive flows microscopically into surface irregularities, creating mechanical interlock and chemical bonding. The elastomeric profile then compresses to seal gaps and rebounds to maintain continuous contact.

Selection Criteria: What Matters Most

| Criterion | Why It Matters | Target Value | SEO Keyword |

| Bond Strength | Prevents strip peel‑off under vibration or wind | ≥ 10 MPa | high‑strength adhesive weatherstrip |

| Temperature Range | Ensures performance in extreme climates | –40 °C to +80 °C | all‑weather seal strip |

| Chemical Resistance | Guards against oils, solvents, cleaners | Class 3 or higher | chemical‑resistant seal strip |

| Compression Set | Ability to rebound after repeated compression | ≤ 15% after 100 cycles | durable foam gasket |

| UV/Ozone Resistance | Prevents aging and cracking outdoors | Pass ASTM D1149 | UV‑resistant EPDM foam |

| Service Life | Long‑term reliability without re‑application | ≥ 10 years | long‑lasting seal strip |

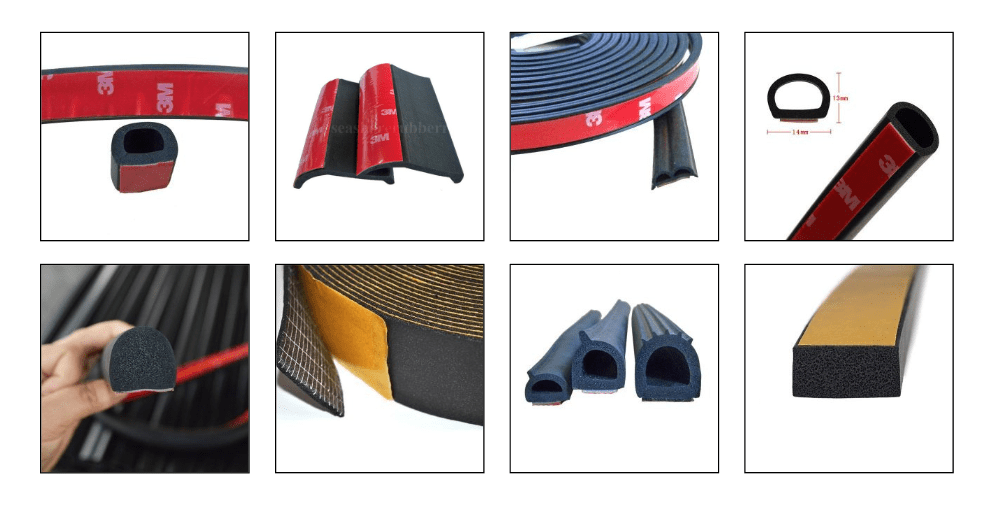

Top Profiles & Key Applications

| Profile Type | Material | Shape | Typical Gap | Key Uses |

| D‑Shape EPDM Foam | EPDM closed‑cell | D‑section | 3–10 mm | Automotive door seals, marine hatches |

| Half‑Round 3M Foam | EPDM high‑density | ½‑round | 5–15 mm | Industrial cabinets, heavy‑duty doors |

| Flat Edging Trim w/ Steel Core | EPDM or silicone | Flat | 1–5 mm | Glass window edging, machine guards |

| P‑Channel Rubber Trim | EPDM solid | P‑section | 2–8 mm | Panel edges, sliding doors |

| Foam‑Backed Vinyl | PVC foam | Custom | 5–20 mm | HVAC duct sealing, refrigeration gaskets |

Real‑World Case Study: Automotive Door Seal

Challenge: A mid‑size SUV experienced wind noise and water leaks around the driver’s door at highway speeds.

Solution: Installed a D‑Shape EPDM foam strip with acrylic adhesive (bond strength 12 MPa, temp range –40 °C / +80 °C).

Outcome:

- Noise reduction of 8 dB at 100 km/h

- Zero water ingress under 2 m simulated rain test

- No adhesive failure after 18 months of field use

Pro Installation Tips

1. Surface Preparation

- Wipe with isopropyl alcohol to remove oil, dust, or wax.

- Ensure surface temperature is between 10 °C and 40 °C for optimal adhesion.

2. Accurate Measurement

- Measure the channel or gap length precisely.

- Cut seal strip slightly longer (≈1%) to maintain compression.

3. Application Technique

- Peel liner gradually as you press the strip into place.

- Use a roller or firm hand pressure to eliminate air pockets.

4. Post‑Install Cure

- Allow 24 hours for full adhesive bond strength to develop before exposing to stress.

FAQ

Q: Can I remove and reposition the strip?

A: Minor adjustments within 5 minutes of application are possible; after that, adhesive sets quickly.

Q: Will the adhesive leave residue?

A: High‑quality acrylic adhesives peel cleanly but test on a sample area if substrate is delicate.

Q: Are these strips paintable?

A: EPDM and foam profiles can be painted with flexible rubber‑compatible coatings.

Why Choose OKIN Seal Strips?

- Material Excellence: 100% virgin EPDM or silicone, free of fillers.

- Robust Production: 21 extrusion lines (6 co‑extrusion, 3 foam) ensure consistent quality.

- Global Reach: Trusted by OEMs in Europe, North America, Middle East; exported to 30+ countries.

- Customization: Any shape, size, or adhesive formulation—tailored to your specification.

Conclusion & Call to Action

Self‑adhesive seal strips deliver unmatched convenience, durability, and versatility across residential, automotive, and industrial sealing applications. Elevate your products’ performance and customer satisfaction by choosing OKIN’s premium adhesive weatherstrips.