Rubber co-extrusion is when rubber and plastic (or rubber) are mixed through specific processing methods. Blends combine the properties of both rubber and plastic (or other rubber). The two materials co-extruded still maintain their respective characteristics. The main purposes of Rubber co-extrusion are as follows:

1.Improve the performance of rubber.

2.Improve the processing performance of synthetic rubber.

3.Reduce costs.

4.Determine the reasonable mixing process method.

5.Development of new polymer materials.

View All ⇊

Rubber extrusion plays a vital role in numerous industries, from automotive to construction, providing essential sealing, insulating, and protective functions. Choosing the right rubber extrusion manu […]

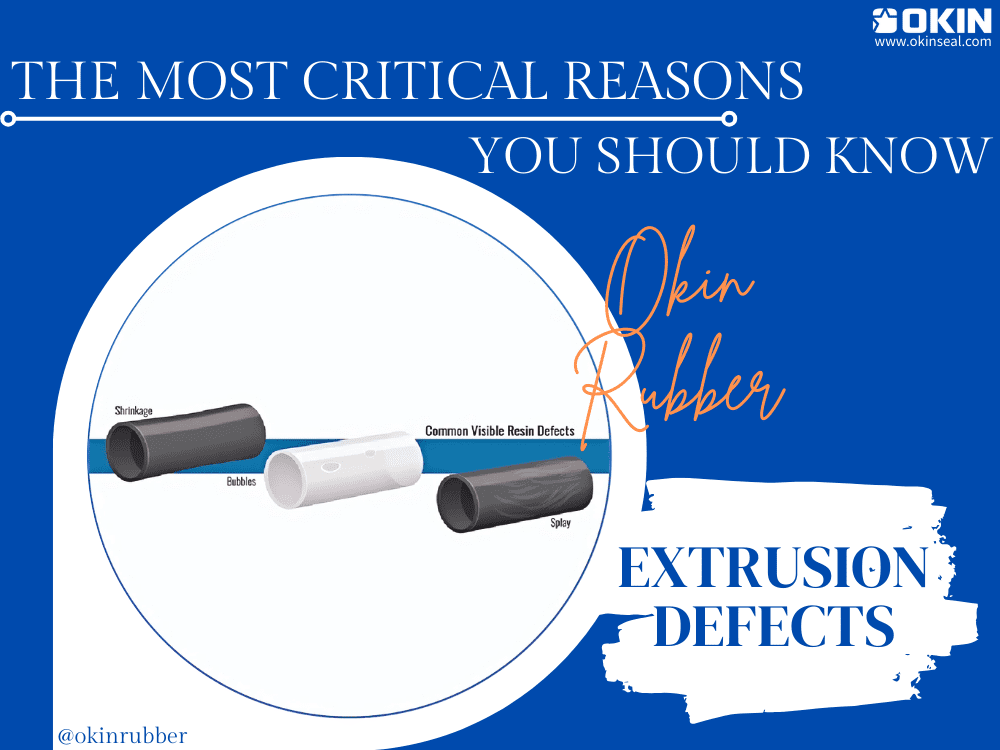

Introduction In the production of rubber seal strips and foam sealing strips, extrusion defects directly affect sealing performance and product lifespan. Knowing common defects, their causes, and prac […]

Overview of Extrusion Definition Extrusion pushes rubber, plastic, or sponge raw materials through a shaped die under heat and pressure, producing continuous profiles with a fixed cross‑section. Benef […]