Nitrile rubber (Nitrile Butadiene Rubber) is a very common material, and we can call it NBR, buna-n rubber, or buna rubber. It is an elastomer made of acrylonitrile and butadiene copolymers and is a synthetic rubber commonly used in various applications. This type of rubber is a common sealing product, which forms a seal between two surfaces and effectively prevents the entry of petrochemicals and oil pollution. This material has excellent oil resistance, heat resistance, and wear resistance, and it is often used in seals in automobile engine compartments.

Nitrile rubber has excellent oil resistance, heat resistance, and sealing properties. It is widely used in industrial fields such as automobile manufacturing, petrochemicals, and aerospace. okin Rubber can manufacture NBR rubber seals of different shapes, sizes, and lengths according to customer specifications and requirements, providing customized solutions for customers around the world.

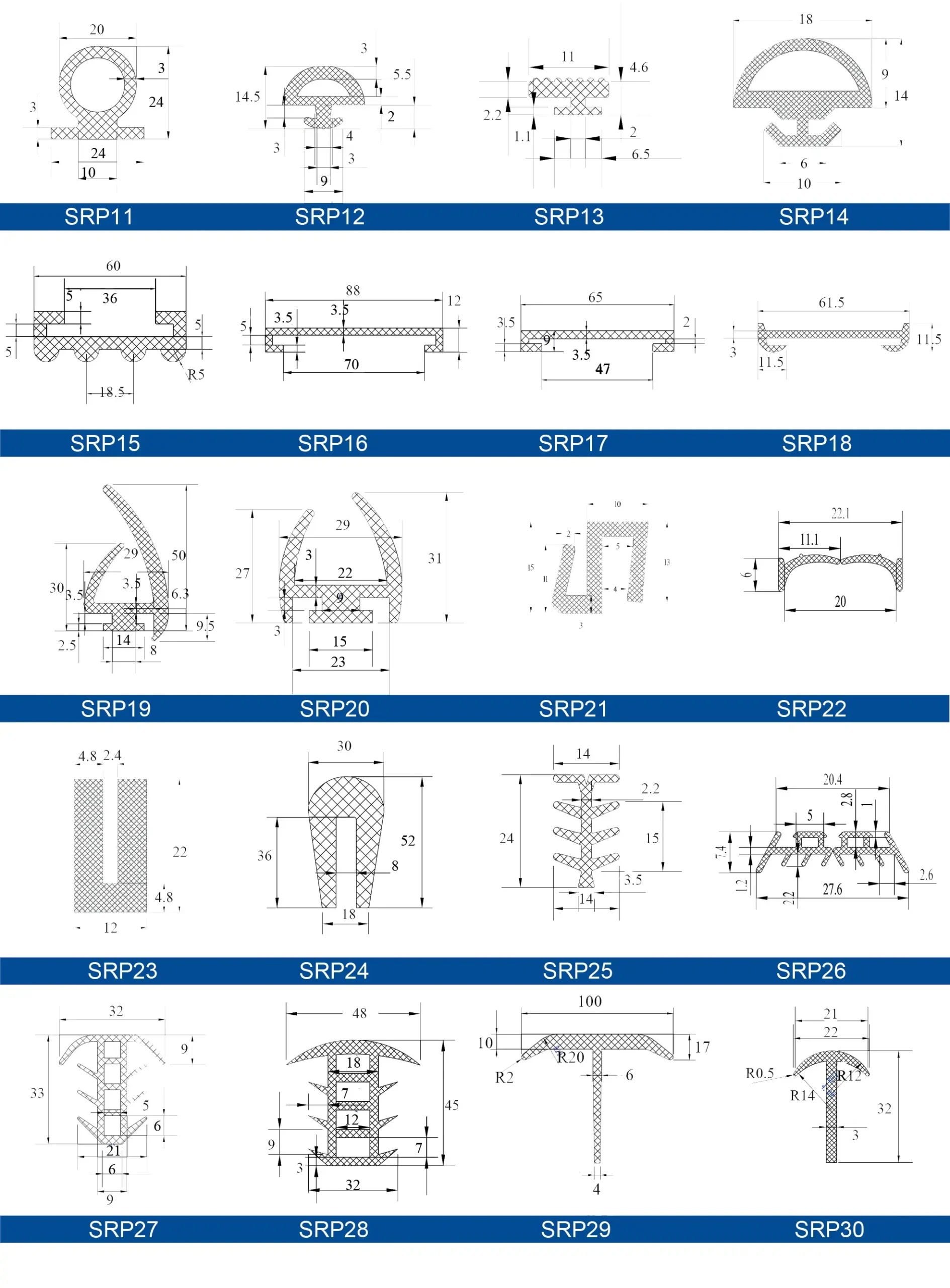

Our factory has a strong manufacturing capacity, so we can provide customers with various thicknesses of nitrile rubber strips. We can ensure the highest quality standards and accurately customize rubber strip products for customers’ specific needs.

In addition, our entire foreign trade team is experienced and can answer your questions online. From the initial product consultation to the delivery and shipment, we will provide high-quality services and the best solutions. Customers from all over the world are welcome to visit our factory.

View All ⇊

okin Rubber's nitrile rubber is available in various colors, sizes, hardness, and grades.

If you need custom nitrile rubber strips, please contact us.

okin Rubber has obtained IATF16949, ISO19001, and ISO14001 certifications. All our materials meet production standards.

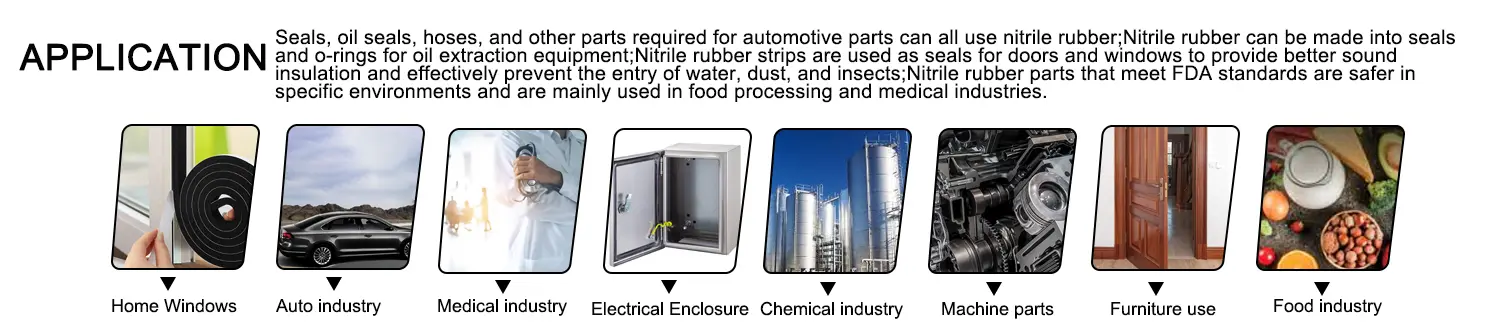

Thanks to its superior oil and chemical resistance, the NBR seal is ideal for various applications and industries.

NBR rubber is widely used in the field of automobile manufacturing. Including automotive seals, oil seals, O-rings, pipes, hoses, suspension parts, and tires. Its resistance to oil and abrasion makes it ideal for automotive parts.

NBR rubber is widely used as a seal material in the industrial field. It is used to seal and isolate liquids, gases, and chemicals. It plays an important role in various mechanical equipment, valves, piping systems, storage tanks, and pumps.

NBR rubber is often used in the manufacture of waterproofing materials, weatherstrips, pipes, and fittings. It is weather and chemical-resistant. It is therefore suitable for both outdoor and indoor sealing and waterproofing applications.

NBR rubber is used in the manufacture of gloves, catheters, seals, and tubing, among others. It can meet the requirements of the medical industry for material safety and reliability.

NBR rubber, also called Buna-N or NBR, is an elastomeric rubber composed of acrylonitrile and butadiene.

Nitrile rubber has an excellent temperature resistance, ranging from -40°C to 120°C (-40℉ - +248℉).

NBR rubber has high tensile strength ranging from 3.5 MPa to 21 MPa, and excellent elongation at break up to 700%.

Nitrile rubber is a rubber material copolymerized by diene and acrylonitrile. Acrylonitrile contains polar cyano groups, and the molecular interaction force of cyano groups is greater than the molecular interaction force of oil. This makes nitrile rubber resistant to erosion by mineral oil and other oils. The content of acrylonitrile directly affects its oil resistance. When the acrylonitrile content is higher, the oil resistance of nitrile rubber is better.

Nitrile rubber is safe. However, we should follow the correct and safe operating specifications during operation. Dust will be generated when processing nitrile rubber, so we should wear masks for protection. Store rubber strips correctly and avoid exposure to high temperatures or humid environments. When using nitrile rubber products, follow the product safety guidelines.

Nitrile rubber itself is not conductive. But we can make it conductive by adding conductive fillers to nitrile rubber. If you need conductive rubber seals, please communicate with professional rubber strip suppliers, and okin Rubber will provide you with specific materials that meet your requirements.

What is NBR Rubber? NBR (Nitrile Butadiene Rubber) is a synthetic rubber made from acrylonitrile (ACN) and butadiene. Known for its excellent oil resistance, NBR is widely used in automotive, oil & […]

When choosing the right rubber material for sealing, insulation, or resistance needs, EPDM and NBR are two of the most commonly used elastomers in the industry. Each material offers distinct advantage […]