Silicone rubber extrusion is a process used to manufacture rubber products. Silicone extrusion products are ideal for several industries. Such as automotive, industrial machinery, electrical cables and wires, and transportation. Silicone rubber has the following advantages:

View All ⇊

The rubber extrusion process is when an extrusion machine forces the synthetic or natural rubber material to take shape through a die under high pressure. The silicone rubber is shaped into a flexible state and then vulcanized to harden the piece into the desired product.

Silicone extrusions are designed to create oven seals, electrical cables and wire insulation, seals, strips, sheets, gaskets, tubes, and other profiles. Silicone rubber extrusion profiles are ideal for several applications. Such as building construction, electric wires, and cables, automotive, industrial equipment, etc.

As one of the reliable silicone rubber manufacturers in China, we can offer a wide array of silicone rubber products in different shapes, thicknesses, colors, and specifications. They include the following types:

Bubble-Seals

D-Sections-Hollow

D-Sections-Solid

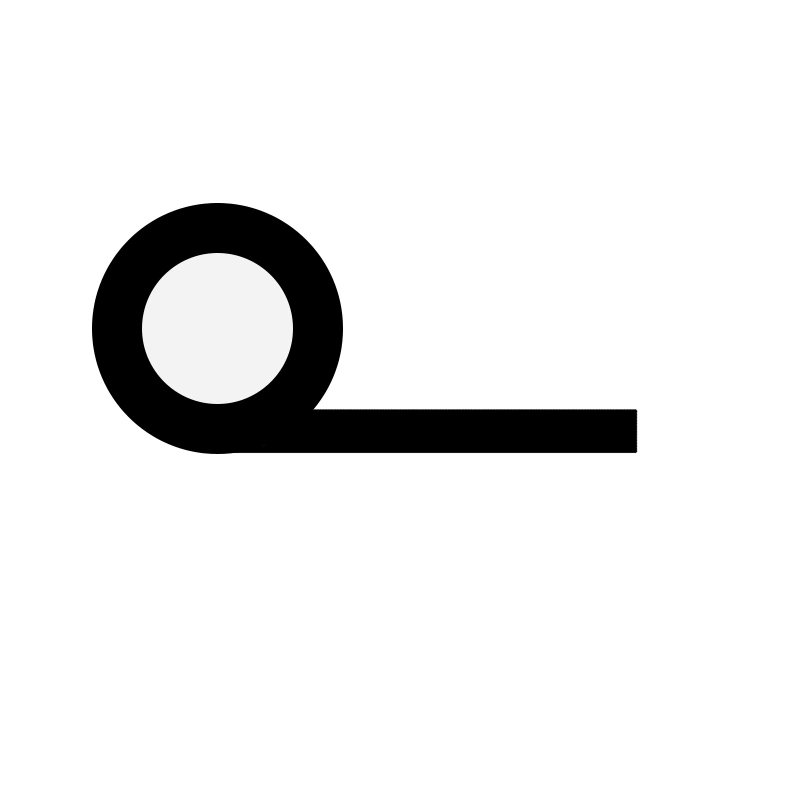

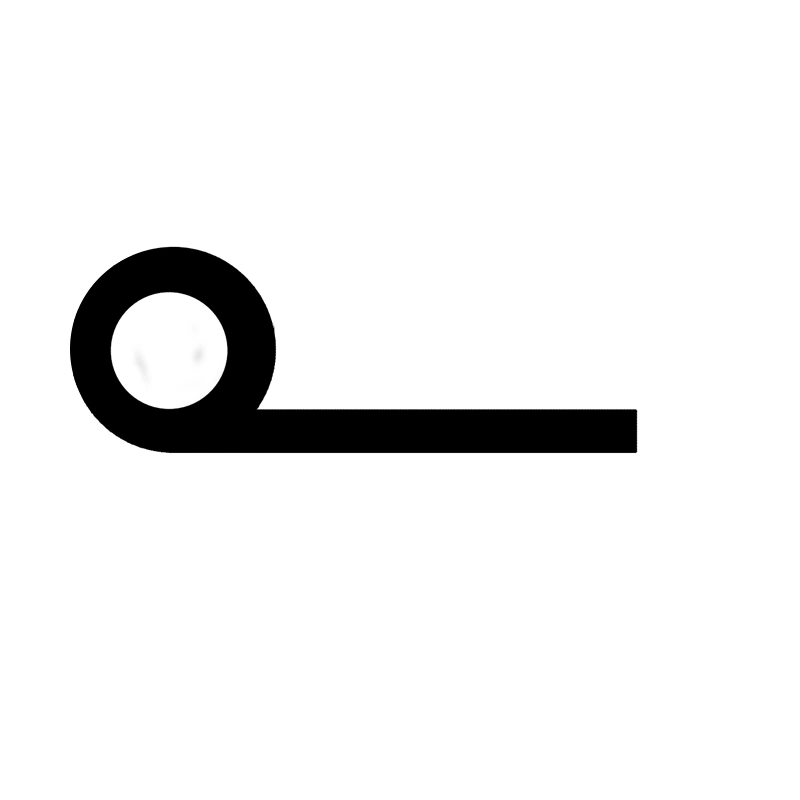

P-Sections-Double

P-Sections-Large

P-Sections-Medium

P-Sections-Small

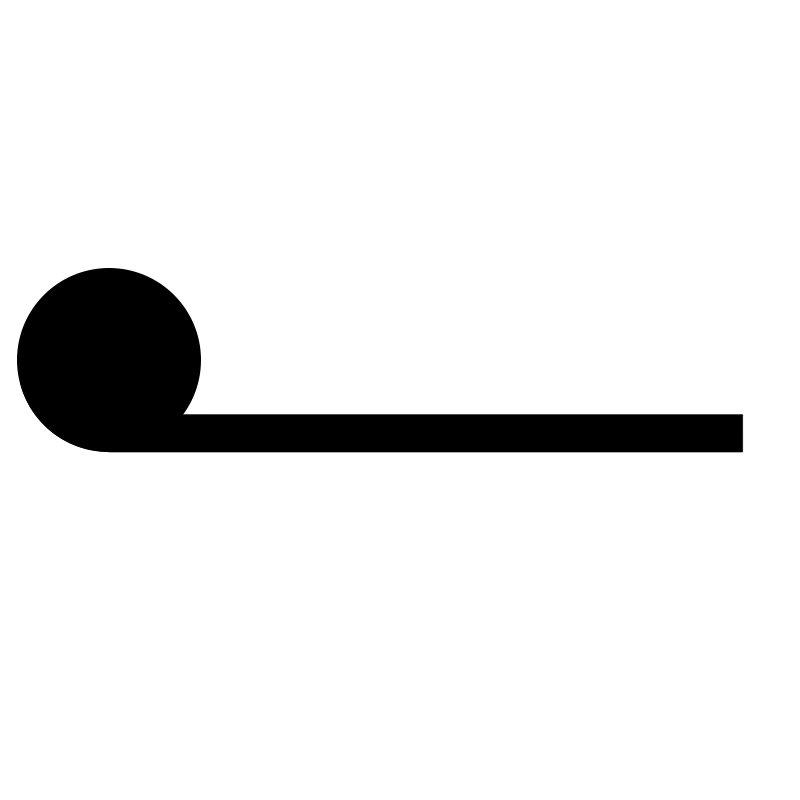

P-Sections-Solid

Silicone-e-Profile

Silicone-H-Profile

Silicone-L-Profile

Silicone-Solid-Cord

Silicone-Sponge-Cord

Square-Sections-Solid

T-Sections

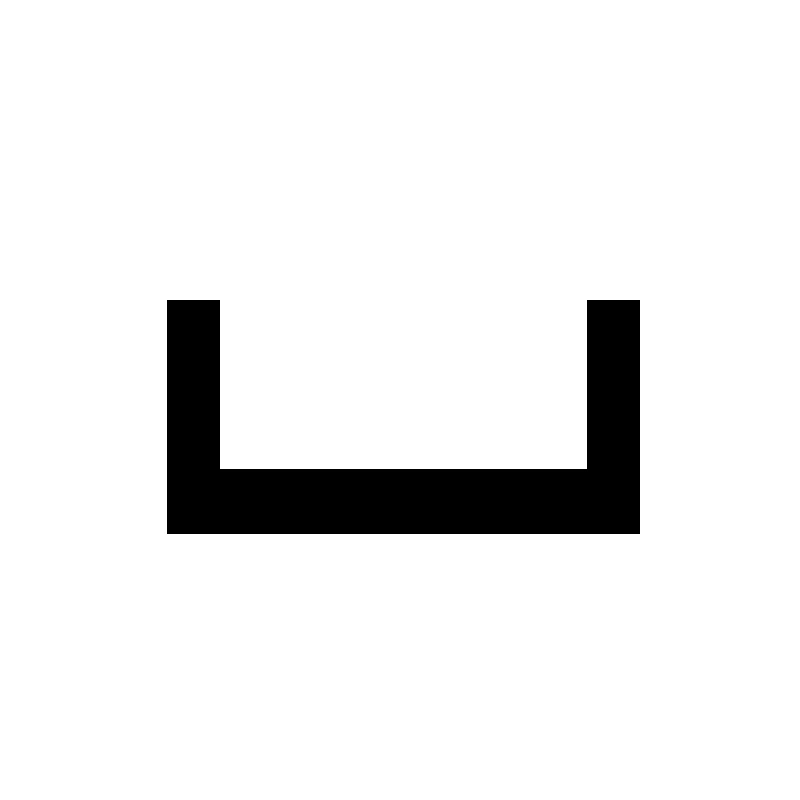

U-Channel-(Clip-on)

Silicone-C-Profile

U-Channels-(Large)

U-Channels-(Medium)

U-Channels-(Small)

Window-Seals

| Grade | Shore Hardness | Temperature Range | introduction | Application |

|---|---|---|---|---|

| General silicone | 40° - 80° | -60 to +200°C | Good overall physical properties. Available in a variety of shore hardnesses. FDA approved. | Auto parts, construction industry, aerospace and medical supplies |

| Very Soft Silicone | 0° - 5° | -60 to +200°C | Has outstanding elasticity and flexibility. The material has a soft feel and is resistant to chemicals. | Seals for specialized machines and equipment, medical applications, arts and crafts |

| Soft Silicone | 5° - 10° | -60 to +200°C | Soft silicone has good temperature resistance. At extremely low temperatures, it can still maintain good flexibility and elasticity. Soft silicone can be used flexibly under a variety of temperature conditions. | Phone cases, keyboard cases, headphone cables |

| Medium Soft Silicone | 15° - 20° | -60 to +200°C | Medium-soft silicone is slightly harder than super-soft silicone. It has good elasticity and can return to its original shape under external pressure. It also has excellent temperature resistance and chemical resistance. | Medical applications, electronic equipment accessories, kitchen appliances, sports equipment |

| Medium Hardness Silicone | 50° - 70° | -60 to +200°C | Medium-hard silicone is flexible enough to protect against external impacts, yet strong enough to maintain its shape, achieving a good balance between softness and rigidity. | Automotive parts, medical supplies, industrial applications, electronic equipment |

| Low hardness silicone | 10° - 35° | -60 to +200°C | Low hardness grade rubber with good mechanical properties | Medical health, toy industry, electronic products, kitchen supplies |

| Medium Hard Silicone | 40° - 60° | -60 to +200°C | Medium hardness silicone combines flexibility with a certain degree of rigidity, being in a state between softness and hardness, maintaining good elasticity and plasticity | Industrial applications, medical supplies, automotive seals, automotive shock absorber parts |

| Hard Silicone | 60° -90° | -60 to +200°C | Hard silicone has a high hardness and can maintain its shape and structure well. It can withstand greater pressure and is not easily deformed. | Industrial seals, automotive parts, oven seals, aerospace sealing materials |

| High temperature silicone | 40° - 70° | -60 to +300°C | High temperature silicone can withstand temperatures up to 300°C and has excellent heat resistance, and can still maintain good working condition under high temperature conditions. | Construction industry, aerospace, automotive manufacturing, medical industry |

| Low temperature silicone | 5° - 80° | Down to -100°C | It can provide longer service life when used in low temperature environment. | Refrigeration industry, aerospace, automobile manufacturing, construction industry |

| Electrically Conductive silicone | 60° - 70° | Up to +200°C | Conductive silicone is a composite material made by adding conductive fillers to ordinary silicone matrix. It is mainly used to achieve conductive connection, shielding electromagnetic interference, etc. | Electronics industry, medical industry, military applications, automotive manufacturing, |

| Platinum Curing Silicone | 40° - 70° | Up to +200°C | Platinum-cured silicone is a silicone material that is rapidly vulcanized using a platinum catalyst. It has extremely high transparency and good biocompatibility, making it very suitable for use in the medical industry. | Medical industry, optical products, automotive manufacturing, aerospace |

| Flame Retardant Silicone | 50° - 75° | -60 to +250°C | Flame retardant silicone can slow down the burning speed of flames and reduce the generation of smoke and toxic gases. | Home appliance industry, public transportation, construction industry, aerospace, and automotive industry |

Silicone rubber is a synthetic elastomer or rubber-like material formed with silicon, oxygen, carbon, and hydrogen atoms. Silicone rubber is known for its unique combination of properties. It is ideal for various applications and industries.

Silicone extrusions can work well under a wide range of temperatures from -60°C to +200°C (-76°F to +392°F).

Silicone rubber extrusions offer exceptional pliability and sealing capabilities. So, silicone extrusions are mainly designed to create seals, strips, tubes, sheets, and gaskets in automotive, aerospace, industrial machinery, and HVAC systems.