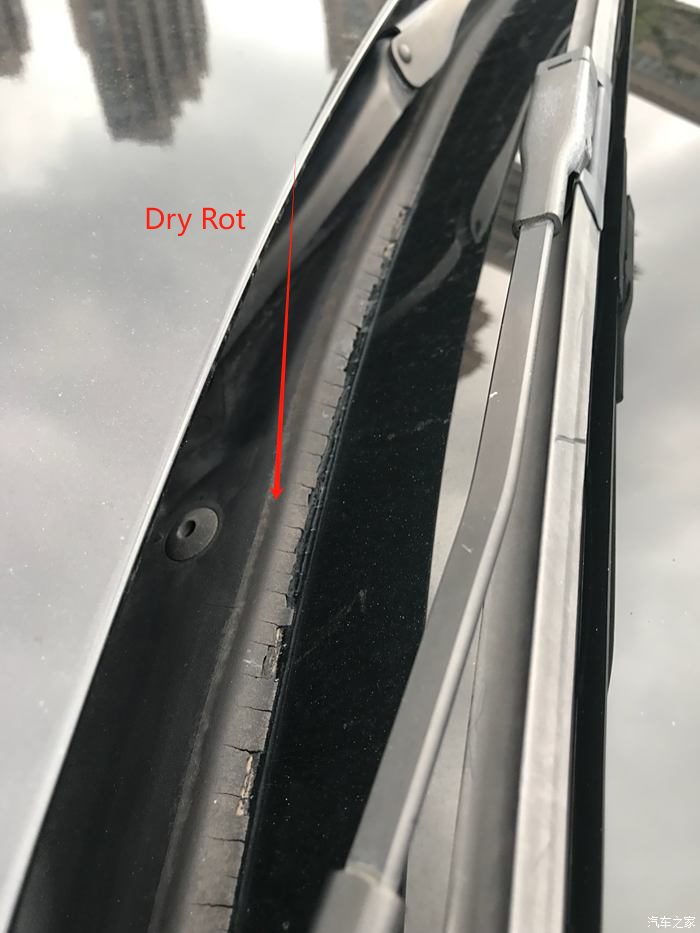

Rubber doesn’t last forever. Over time, it degrades and wears out. Under harsh conditions, it may crack or snap, appearing dry and brittle — a phenomenon often referred to as rubber dry rot.

Have you ever had to replace an old rubber seal strip on a door or window? Even if the door or window wasn’t used frequently, the rubber might have still become stiff, cracked, or easily broken with just a slight bend. That’s essentially what we call dry rot in rubber.

In this article, we’ll explain what rubber dry rot is, why it happens, and how you can protect your rubber seal strips from premature aging. Whether you’re a homeowner, car owner, or part of the rubber seal strip industry, this guide will offer you valuable insights.

What Is Rubber Dry Rot?

Rubber dry rot doesn’t involve actual biological decay like organic materials experience. Typically, fungi cause organic rot, but fungi cannot break down rubber. Instead, “dry rot” describes the appearance and behavior of rubber that has become brittle, cracked, and dry over time.

Rubber — especially synthetic types — is incredibly durable, known for its flexibility, elasticity, and resistance to wear. It’s made through chemical processes that make true rotting impossible. However, when rubber ages, it loses elasticity and eventually cracks or flakes, mimicking the look of dry rot.

What Causes Rubber Dry Rot?

Several factors contribute to the deterioration of rubber weather stripping:

1. Natural Aging

All rubber products have a limited lifespan. As rubber ages, its chemical structure degrades, leading to loss of flexibility and the formation of cracks. While aging is inevitable, you can slow it down by minimizing exposure to heat, moisture, and UV radiation.

2. Temperature Extremes

Rubber performs best within specific temperature ranges. For instance, EPDM rubber remains stable between -50°C to +150°C (-58°F to 302°F). Prolonged exposure to temperatures beyond these limits can soften, deform, or crack the material.

Frequent temperature fluctuations also cause rubber to expand and contract repeatedly, accelerating dry rot.

3. UV Radiation Exposure

UV light — especially sunlight — breaks down the molecular bonds in rubber through a process called photodegradation. Over time, UV damage makes rubber seal strips brittle and prone to cracking.

Importantly, UV radiation isn’t limited to sunlight; artificial UV sources can also cause damage, so indoor environments aren’t always safe by default.

4. Harsh Weather Conditions

Outdoor rubber seal strips face rain, snow, humidity, and wind daily. Moisture can cause swelling and shrinking cycles, leading to cracks. Dust and debris carried by wind can also accelerate surface erosion, weakening the rubber.

5. Lack of Use and Poor Storage

Rubber seal strips that are left unused for long periods can stiffen and lose elasticity. Additionally, improper storage — especially in places with high heat, moisture, or UV exposure — can cause premature dry rot.

To ensure long-term durability, proper storage practices are critical.

How to Prevent Dry Rot in Stored Rubber Weather Stripping

Preventing dry rot is far easier than trying to fix it. Here’s how you can protect your stored rubber seal strips:

– Keep Rubber Away from Sunlight

Store rubber products in dark, shaded areas away from direct sunlight to avoid UV degradation.

– Store in a Cool, Dry Place

Heat and humidity accelerate the aging process. Ensure proper ventilation and maintain a low-humidity environment.

– Maintain a Consistent Temperature

Sudden changes in temperature can cause rubber to expand and contract, leading to premature cracking. Choose a storage location with a stable climate.

– Use Airtight Bags

Sealing rubber seal strips in airtight bags helps protect them from moisture, oxygen, and dust exposure.

– Apply Rubber Protectants

A rubber protectant can create a light barrier on the surface, slowing down aging and protecting against UV rays, ozone, and other environmental factors.

Other Common Rubber Problems

Besides dry rot, rubber products may face:

- Cracking: Caused by aging, UV, or chemicals.

- Discoloration: Fading, yellowing, or staining due to UV exposure and pollutants.

- Hardening: Cold temperatures reduce flexibility.

- Swelling or Shrinking: Due to moisture absorption or drying out.

- Surface Deformation: High heat, pressure, or poor storage leads to warping or blistering.

- Stickiness: Breakdown of rubber compounds over time.

- Pitting/Erosion: Caused by continuous friction.

- Powdery Dust: Migration of protective waxes to the surface.

FAQs

Can Dry Rot on Rubber Seal Strips Be Fixed?

No. Once rubber dry rot sets in, the material becomes brittle and loses its structural properties. While you can’t reverse the damage, you can prevent it through proper storage and regular maintenance.

How Long Does It Take for Rubber to Dry Rot?

It varies based on the type of rubber and environmental conditions. Natural rubber may show signs of dry rot in 3–5 years, while high-quality synthetic rubbers like EPDM can last 20 years or more outdoors.

Is 100% Natural Rubber Biodegradable?

Yes, natural rubber, sourced from rubber trees, is biodegradable. However, the decomposition process is slow and can take months to years. Synthetic rubbers, made from petrochemicals, are generally not biodegradable.

Why Is Recycling Rubber So Difficult?

Rubber is tough to recycle due to the vulcanization process, which chemically cross-links the rubber molecules, making them resistant to melting and reshaping.

Conclusion

Rubber dry rot isn’t a biological rot but rather a deterioration process where rubber loses its elasticity and becomes brittle. By understanding the causes — such as UV exposure, temperature extremes, moisture, and improper storage — you can take proactive steps to protect your rubber seal strips and extend their service life.

Proper storage, minimizing exposure to harsh elements, and occasional maintenance are the keys to keeping your rubber products in great shape for years to come.