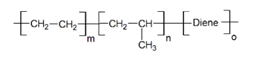

What Is EPDM Rubber?

EPDM (Ethylene Propylene Diene Monomer) is a synthetic rubber renowned for its exceptional weather, heat, ozone, and electrical insulation properties. It is widely used for sealing, insulation, and vibration‐damping applications in industrial, automotive, HVAC, and construction sectors.

Key Physical and Chemical Properties of EPDM

| Property | Value | Notes |

| Temperature Range | –50 °C to +150 °C | Performs in extreme cold and heat |

| Tensile Strength | 15–25 MPa (≈ 2175–3625 psi) | Withstands high mechanical stress |

| Elongation at Break | 200–600% | Excellent elasticity and resilience |

| Hardness | 40–90 Shore A | Available in a wide hardness range |

| Ozone Resistance | Excellent | Long‐term outdoor durability |

| Chemical Resistance | Acids, Alkalis, Polar Fluids | Resistant to many corrosive media |

| Electrical Insulation | >20 kV/mm | Ideal for electrical and cable applications |

Eight Key Advantages of EPDM

- Weather & UV Resistance: Remains crack‑free and flexible after 20+ years outdoors.

- Wide Temperature Tolerance: From –50 °C up to +150 °C.

- Chemical Resistance: Resists dilute acids, alkalis, ketones, hydraulic fluids.

- High Elasticity & Fatigue Resistance: Fully rebounds after repeated compression.

- Electrical Insulation: High dielectric strength for safe electrical use.

- Manufacturing Flexibility: Extrusion, molding, die‑cutting, multi‑layer co‑extrusion.

- Non‑Toxic & Low Odor: Complies with RoHS and REACH, safe for contact applications.

- Cost‑Effective: Long service life reduces replacement and maintenance costs.

Typical Applications

| Application Sector | Key Components | Benefits |

| HVAC & Construction | Window/door seals, roofing membranes | Airtight, watertight, energy saving, noise reduction |

| Automotive | Door/trunk seals, engine gaskets, vibration pads | Water‑proof, dust‑proof, sound dampening, UV resistant |

| Industrial Machinery | Flange gaskets, hydraulic seals | Chemical resistance, high‑pressure tolerance, fatigue resistance |

| Rail & Transit | Floor liners, door seals | Flame‑retardant, low smoke, fire spread inhibition |

| Electrical & Electronics | Cable jackets, insulation grommets | High dielectric strength, safety insulation |

| Appliances | Refrigerator door seals, AC gaskets | Low‑temperature performance, superior sealing |

Why Choose OKIN’s EPDM Seals?

- Premium Raw Materials: ≥70% pure rubber content, steel‑reinforced.

- Robust Production Capacity: 21 extrusion lines (6 co‑extrusion, 3 foam), 7 automatic corner‑cutting machines.

- Quality Certifications: ISO9001, IATF16949, RoHS, REACH.

- Global Reach: Stable exports to Southeast Asia, Northern Europe, Middle East, Europe, North America.

- Custom Solutions: Free sample design, 3–7 days rapid prototyping, multiple hardness and color options.

Contact us for free samples & technical specifications!