Overview of Extrusion

Definition

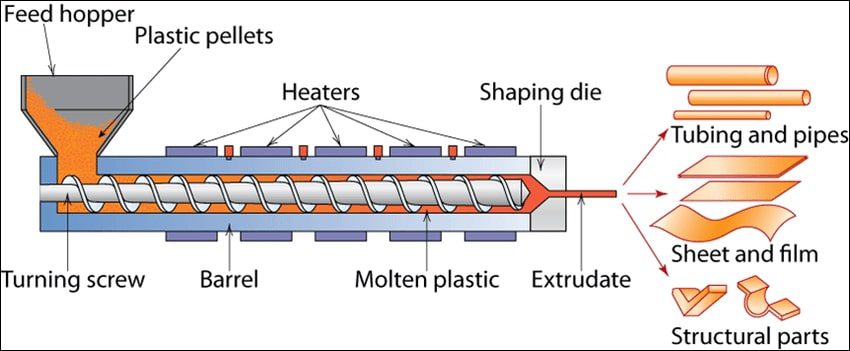

Extrusion pushes rubber, plastic, or sponge raw materials through a shaped die under heat and pressure, producing continuous profiles with a fixed cross‑section.

Benefits

- Automatic, continuous operation

- High throughput for B2B production

- Low labor requirement and cost‑effective

- Excellent surface finish and mechanical properties

Extrusion vs. Co‑extrusion

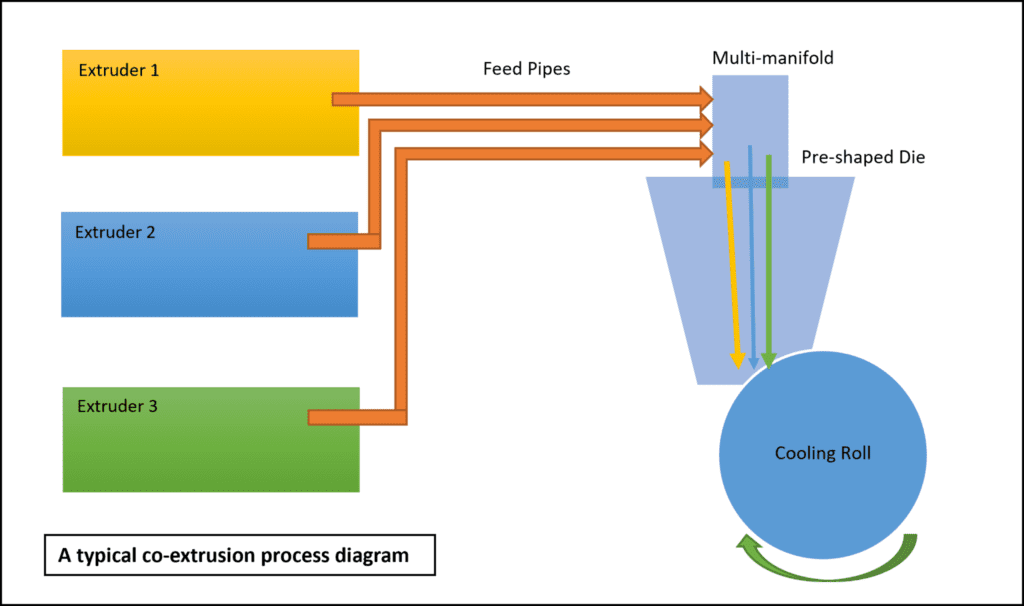

| Feature | Extrusion (Single‑layer) | Co‑extrusion (Multi‑layer) |

| Layers | One | Two or more |

| Equipment | Single extruder | Multiple extruders + manifold die |

| Cost | Lower | Higher |

| Control Parameters | Pressure, temperature, speed | Individual layer flow, adhesion |

| Typical Applications | Basic seals, edge trims | Dual‑hardness seals, metal/nylon‑insert seals |

Materials & Key Parameters

| Material | Form | Typical Profiles | Key Process Factors |

| Rubber | Sheet/Block | D, P, T, U, J, V shapes | High‑shear mixing, precise heating |

| Sponge | EPDM granules | Closed‑cell gaskets | Foaming agent ratio, uniform cell structure |

| Plastic | PVC/TPV/TPE granules | Window & door trims | Melt temperature, additive compatibility |

Typical Extrusion Workflow

- Feeding

Raw materials loaded into hopper. - Heating & Mixing

Screw rotation heats, plasticizes, and conveys material. - Shaping

Molten mass forced through die to form desired cross‑section. - Cooling

Profiles solidify in water bath or air‑cooling unit. - Cutting & Collection

Automatic cut to length or coil for shipment.

Okin Rubber’s Capabilities

- 21 extrusion lines: 6 co‑extrusion, 3 foam‑extrusion, 7 corner‑jointing machines

- Materials: EPDM, Neoprene (CR), NBR, PVC, TPV, TPE

- Custom Profiles: Any cross‑section, dual‑hardness, metal/nylon inserts, flocked seals

- Quality Features: High rubber content, steel reinforcement, superior air/water tightness, flame‑retardant, corrosion‑resistant

Key Applications

- Window & Door Seals: Improved insulation, weatherproofing

- Automotive Seals: Vibration damping, long‑term durability

- Appliance Gaskets: Dust‑ and leak‑proof for refrigerators, washers

- Marine & Container Seals: Corrosion resistance, high elasticity

Conclusion

With advanced extrusion and co‑extrusion technology, diverse material expertise, and strong customization, Okin Rubber (OKIN) delivers high‑performance seal strips to global B2B clients. From single‑layer to multi‑layer, rubber to sponge to plastic, we guarantee top quality at competitive prices. Contact us today!