Fire Door Strips Features

|

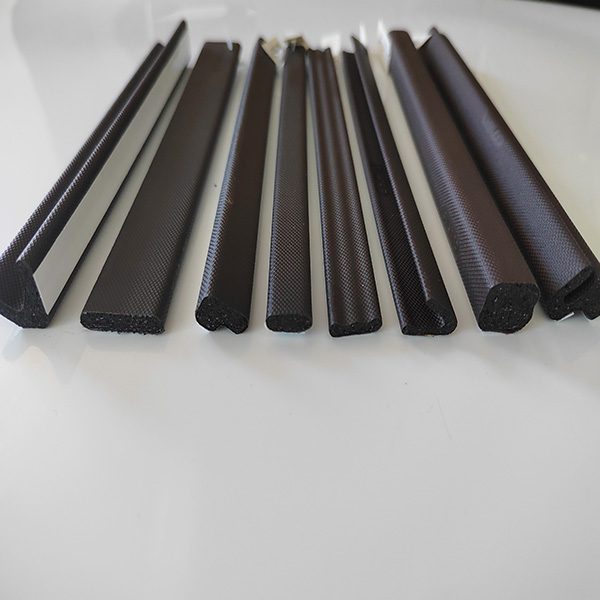

Material

|

PU foam, Graphite intumescent material, Flame-resistant material

|

|

Color

|

Brown

|

|

MOQ

|

3,000 meters

|

|

Packing

|

Packed in rolls with cartons or customized to customer needs

|

|

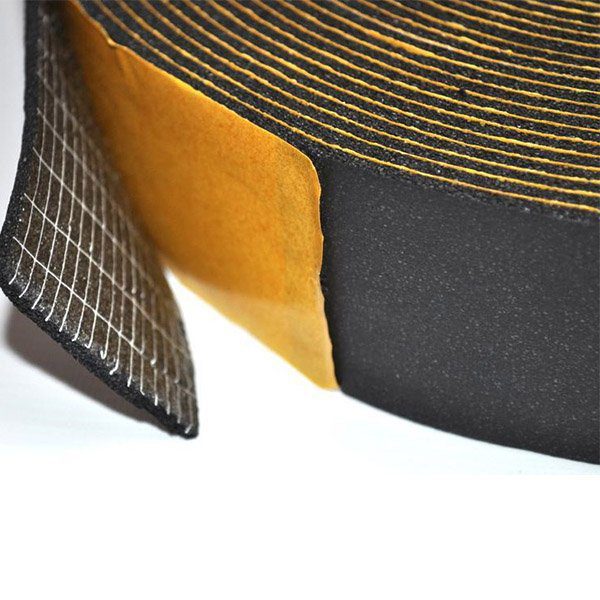

Manufacturing process

|

Made of PE film and liquid PU foam through dispensing technology and thermoplastic process combined.

|

Fire Door Seal Technical Data Sheet

| Serial No. | Test Item | Standard Requirements | Field Test Results | Single Decision |

| 1 | Appearance | Pressure pit, uneven thickness, swelling body, obvious fall off or powder, and other defects. | It fits the bill | Qualified |

| 2 | Allowance for size | Width deviation ± 10% | 0.75% | Qualified |

| Thickness deviation ± 10% | 0.66% | |||

| 3 | Intumescent performance | The deviation between the ratio of the intumescent body and n。announced by the company ≤15% | 4.50% | Qualified |

| 4 | Aging resistance | Press the surface of the fire door intumescent strip body after the test with a glass rod, has no obvious powder and falling off. | It fits the bill | Qualified |

| The ratio of the intumescent body after the test is not less than the initial ratio n. | 21.06ml/g | Qualified | ||

| 5 | Moisture resistance | After the water resistance test, the fireproof intumescent seal strip have no obvious corrosion, swelling, powder and falling off. | It fits the bill | Qualified |

| The rate of the composite expansion body after the water resistance test is not more than 5%. | 2.32% | Qualified | ||

| The fireproof intumescent seal strip after the water resistance test is not less than the initial ratio n. | 21.06ml/g | Qualified | ||

| 6 | Acid resistance | After the acid resistance test, the fireproof intumescent seal strip has no obvious corrosion, swelling, powder and falling off. | It fits the bill | Qualified |

| The rate of the composite expansion body after the acid resistance test is not more than 5%. | 2.53% | Qualified | ||

| The fireproof intumescent seal strip after the acid resistance test is not less than the initial ratio n. | 20.73ml/g | Qualified | ||

| 7 | Alkali resistance | After the alkali resistance test, the fireproof intumescent seal strip has no obvious corrosion, swelling, powder and falling off. | It fits the bill | Qualified |

| The rate of the composite expansion body after the alkali resistance test is not more than 5%. | 2.03% | Qualified | ||

| The fireproof intumescent seal strip after the alkali resistance test is not less than the initial ratio n. | 20.16ml/g | Qualified | ||

| 8 | Signs | Conformity label, the label shall be affixed correctly, content and products consistent | It fits the bill | Qualified |

| 9 | Packing | Packing should be in line with the “Packaging Inspection Reference” requirements, carton printing should meet the requirements, packaging belt tightness moderate, turns meet the requirements | It fits the bill | Qualified |

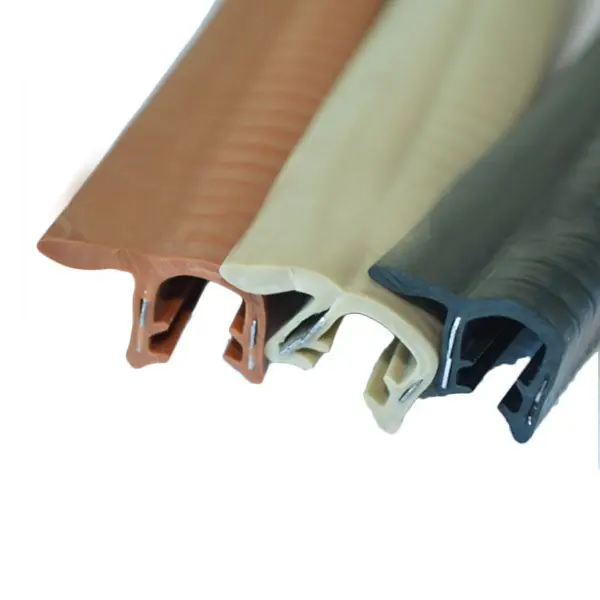

Fire Strips Applications

- Timber fire door

- Fire proof window and door

- Fire proof glass door

Advantages of Intumescent Strips

- Excellent fire resistance, tight sealing effect.

- Strong adhesive with double-sided tape, stable to fix in the right place, easy to install.

- High-density PU foam, excellent sound insulation.

- This fire door strip is environmental friendly and it can bring a safe and healthy life.

- Protective PE film helps prevent aging, tear, and corrosion, providing a long service life.

- Tough materials with smooth coating, durable to use.

- It swells up when exposed to fire, to keep a stable sealing effect.