| Material | NR / NBR / EPDM / Silicone |

| Metal Insert | Zinc-plated Carbon Steel / Stainless Steel |

| Working Temperature | -40°C to +120°C (depending on rubber type) |

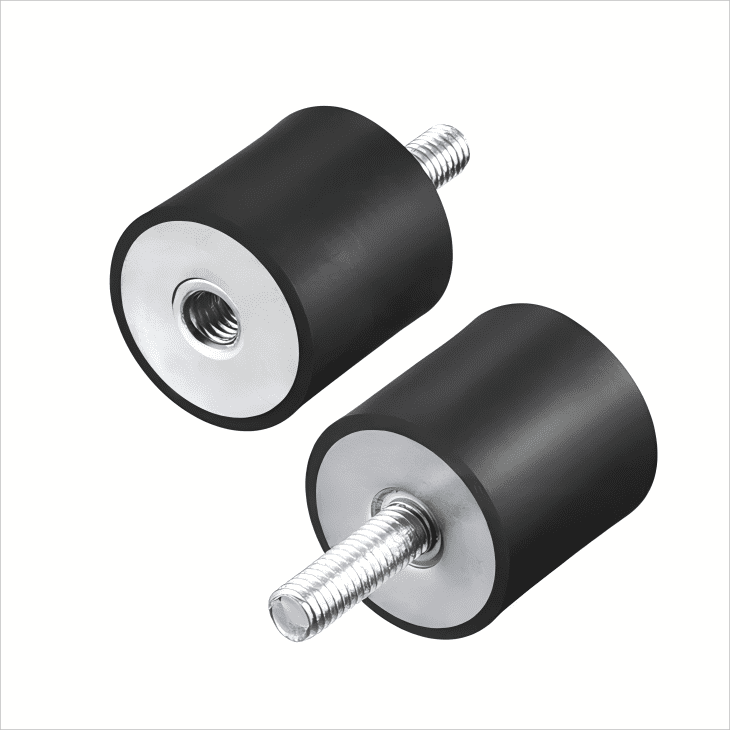

| Mounting Type | Male-Male, Male-Female, Female-Female |

| Standard Sizes | M4~M12 thread, Diameter 10–100mm |

| Applications | Compressors, Pumps, Generators, HVAC Units |

Product Features

Our rubber isolators are made of high-performance rubber and molded using precision molding technology, combining excellent elasticity, durability, and exceptional resistance to cutting and tearing.We offer two variants of metal compound, carbon steel and stainless steel, which not only provide structural stability, but also give our products excellent corrosion resistance. With Shore A hardness options from 40 to 70, these isolators are capable of handling both active and passive vibrations while maintaining stability under dynamic load.

Product Advantages

These shock absorbers have excellent kinetic energy absorption efficiency, which can significantly inhibit vibration transmission, effectively protect precise equipment and maintain its long-term operational accuracy. By adopting a unique compression process, metal inserts with threaded bolts or sockets are firmly integrated with the rubber lining to ensure that they never relax during installation. Compared to conventional poles, our products use a rubber antiaging formula that can withstand extreme temperatures, the oil environment, and ozone erosion for a long time, and still maintain stable performance under harsh conditions.

Application Fields

Ideal for compressors, HVAC units, generators, electronic enclosures, automotive systems, air pumps, industrial machinery, and medical devices, these isolators are widely used across agriculture, construction, and automation industries. The product is available in male-male, male-female, and female-female configurations to meet various installation needs.