What is NBR Rubber?

NBR (Nitrile Butadiene Rubber) is a synthetic rubber made from acrylonitrile (ACN) and butadiene. Known for its excellent oil resistance, NBR is widely used in automotive, oil & gas, aerospace, and general industrial sealing applications.

Key properties of NBR:

- Excellent resistance to oils, fuels, and greases

- Good tensile strength and abrasion resistance

- Stable performance in temperatures from -30°C to +100°C

- Cost-effective and versatile for many applications

What is HNBR Rubber?

HNBR (Hydrogenated Nitrile Butadiene Rubber) is a high-performance rubber derived from NBR through a hydrogenation process. This process significantly improves its temperature resistance, chemical stability, and mechanical strength, making HNBR suitable for harsh or demanding conditions such as automotive engines, oil drilling, and hydraulic systems.

Key advantages of HNBR:

- Wider temperature range: -40°C to +160°C

- Superior chemical resistance

- Low compression set for long-term sealing reliability

- Higher durability under pressure and friction

- More expensive than NBR but ideal for critical applications

🔍 NBR vs HNBR: Side-by-Side Performance Comparison

| Property | NBR Rubber | HNBR Rubber |

| Temperature Resistance | -30°C to +100°C | -40°C to +160°C |

| Oil & Fuel Resistance | Excellent | Superior |

| Chemical Resistance | Good | Better, especially against acids and bases |

| Tensile Strength | 200 – 3,500 PSI | 1,500 – 3,500 PSI (Higher) |

| Wear & Abrasion Resistance | Strong | Stronger and more durable |

| Compression Set | Moderate | Lower, retains shape better |

| Cost | Lower, cost-effective | Higher, for high-spec use |

🔧 Typical Applications of NBR and HNBR

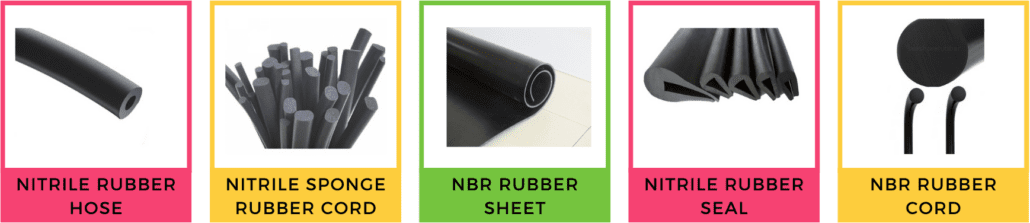

Common uses of NBR:

- Automotive: seals, fuel hoses, O-rings

- Industrial equipment: hydraulic seals, gaskets

- Consumer & medical: gloves, flexible tubing

HNBR is ideal for:

- Engine seals and timing belts

- Hydraulic systems in high-temperature/pressure conditions

- Oil and gas industry components

- Sealing applications in chemical processing equipment

🤔 Which Material Is Right for You?

Choosing between NBR and HNBR depends on your specific application needs. Here’s how to decide:

✅ Step 1: Evaluate Your Application Conditions

- Will the rubber face high or low temperatures?

- Will it be exposed to oils, fuels, chemicals, or pressure?

- Does it require long-term mechanical strength?

✅ Step 2: Balance Performance with Budget

If your application involves extreme heat, chemicals, or pressure, HNBR is the better option. For cost-conscious and moderate conditions, NBR is a practical and reliable choice.

✅ Step 3: Get Expert Advice

Since rubber compounds can vary by formulation, it’s best to consult a professional rubber extrusion manufacturer to choose the most suitable material for your project.

📢 Conclusion: Select the Right Rubber with Confidence

In summary, NBR offers excellent oil resistance and affordability, making it ideal for general sealing needs. HNBR, thanks to its hydrogenated structure, delivers superior resistance to heat, chemicals, and wear—perfect for high-performance applications.

If you’re not sure which rubber to choose, contact Taiwan Okin Huasu Group Limited for tailored technical advice, competitive pricing, and professional service.