What Is PPAP?

The Production Part Approval Process (PPAP) is an industry-standard method—originating in automotive and aerospace—to confirm that a supplier can consistently produce parts meeting all design specifications and quality requirements. PPAP comprises 18 core elements (e.g., Design Records, PFMEA, Control Plan, PSW) and sits within the broader Advanced Product Quality Planning (APQP) framework.

Why PPAP Matters?

- Ensure Consistency

Verifies every production run meets design and performance criteria, preventing costly rework or recalls. - Reduce Risk

Employs Statistical Process Control (SPC) and Failure Mode and Effects Analysis (FMEA) to identify and eliminate potential issues early. - Build Trust

Standardized deliverables (such as the Part Submission Warrant) give customers confidence in reliable, on‑time delivery.

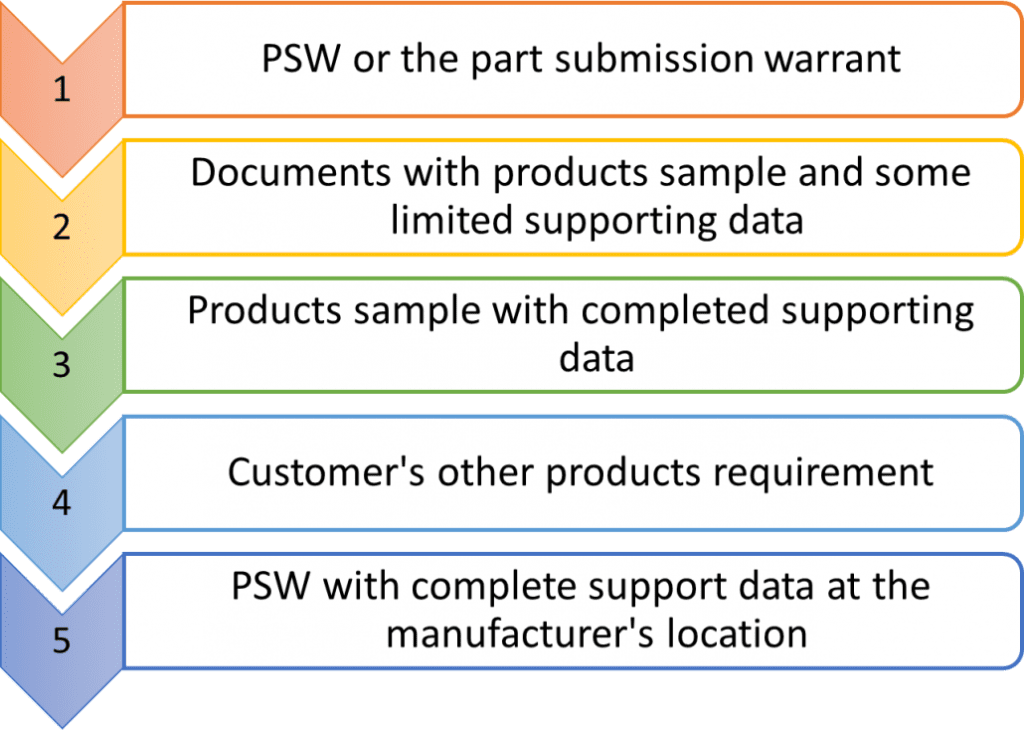

The Five Levels of PPAP Submission

| Level | Submission Content | Typical Use Case |

| 1 | Part Submission Warrant (PSW) only | Quick capability confirmation |

| 2 | Product samples + limited supporting data | Small pilot runs |

| 3 | Product samples + complete supporting data | Standard default for full approval |

| 4 | Customer-specific requirements | Special tests or custom documentation |

| 5 | PSW + complete data at supplier’s site | Most stringent, includes on‑site audit |

Note: Level 3 is the default for most new projects. Levels 4–5 apply when customers request extra validation.

The 18 Core Elements of PPAP

- Design Records

- Engineering Change Documents

- Engineering Approval Evidence

- DFMEA (Design Failure Mode and Effects Analysis)

- Process Flow Diagram

- PFMEA (Process Failure Mode and Effects Analysis)

- Control Plan

- MSA (Measurement System Analysis, e.g., GR&R)

- Dimensional Results

- Material Performance Test Results (DVP&R)

- Initial Process Studies (SPC)

- Qualified Laboratory Documentation

- Appearance Approval Report (AAR)

- Sample Parts

- Engineering Approval Sample

- Checking Aids (inspection fixtures)

- Customer-Specific Requirements

- Part Submission Warrant (PSW)

PPAP vs. APQP

| Aspect | PPAP | APQP |

| Focus | Part approval & process validation | End‑to‑end product quality planning |

| Documentation | 18 required elements | Five phases with defined gates |

| Process stage | Falls under APQP Phase 4 (Validation) | Phases: Planning → Design → Process → Validation → Launch |

| Goal | Confirm supplier’s readiness for mass production | Proactively manage risks from concept to launch |

When Is PPAP Required?

- First production run of a new part

- Design or material changes

- Process changes (methods, tooling, inspection)

- Reactivating tooling inactive for over one year

OKIN’s Competitive Edge in Rubber Sealing Strips

- Premium Materials: High‑purity rubber, superior corrosion and aging resistance

- Customization: Any shape, co‑extrusion, foam, flocked profiles

- Capacity: 21 extrusion lines (6 co‑extrusion, 3 foam), 7 angle‑jointing machines

- Global Reach: Exports to North America, Europe, Southeast Asia, Middle East

- Quality Control: Integrated SPC + FMEA + PPAP for every order

Conclusion

PPAP’s five submission levels provide clear steps for part approval, while its 18 elements ensure consistency and reliability. OKIN Rubber combines rigorous PPAP processes with global production capacity to deliver top‑quality sealing strips. By sharing expert PPAP insights on LinkedIn, Facebook, Instagram, and optimizing for Google, OKIN strengthens brand authority and drives targeted B2B leads.