Rubber extrusion is a cost-effective manufacturing process to produce rubber products. It is superior to other production methods in the volume of wasted materials in the rubber extrusion process and the cost to produce the final extruded rubber seals. Rubber extruded seals are designed to provide a tight seal for doors, windows, trims, and edges in various applications. Including automotive, construction, marine, electrical appliances, industrial equipment, engineering, and other manufacturers.

Okin Rubber is a reliable rubber extrusion manufacturer. We can offer Silicone, EPDM, CR, NBR, Neoprene, Viton, and Buna-N rubber extrusions. Rubber products we can supply include epdm extrusions, Neoprene Extrusion (CR), NBR extrusions, rubber shock absorbers, EPDM flame-resistant door seals, container sealants, pore foam extrusions, cable protection rings, rubber gate sealants, self-adhesive tape, silicone extrusions and special rubber extrusions (HNBR, FKM and Viton). We can also supply adhesives if needed. In addition, we can produce rubber extrusions to order according to customer samples or drawings. If you are interested, do not hesitate to contact us.

MOQ: 500m

View All ⇊

Qingdao okin Industrial Co., Ltd. is a professional and reliable rubber extrusion manufacturer. Our factory has a high production capacity, and our products have been exported to many countries. We have 20 years of experience in rubber extrusion. Our company has the confidence and strength to work with more global companies. We provide the best rubber sealing strips and extruded seals for specific needs. Our company has advanced co-extrusion lines, rubber injection machines, and mature CAD and CAM mold research, development, and manufacturing capabilities. As an extrusion manufacturer company, we have a team of skilled technicians and engineers. They ensure quality and safety at every step of the production of rubber extrusion products. All the products manufactured are in line with the international and industry standards.

We believe that high-quality products and excellent customer service are crucial to building long-term and reliable relationships with our customers. Undoubtedly, global partnerships make us a competitive player and also keep us at the forefront of international trends, products, and processes. We strive to be a reliable, knowledgeable, and visionary rubber extrusion supplier, offering quality products, affordable prices, and excellent customer service at home and abroad.

Also, we value innovation and are committed to exploring new materials and rubber extrusion manufacturing technology to help our customers meet their expectations. We use top-quality rubber polymers to produce custom rubber extrusions tailored to your needs. If you are interested, please contact us for a quotation, catalog, MOQ, and more.

Okin Rubber has passed many international and industry quality and management certifications. These let us offer global customers reliable rubber extrusion supply chains. We designed and built a full set of process equipment inside the company.

It ensures that the rubber extrusion products meet the customer’s standards. Every manufacturing process meets the specific quality standard. Our internal standards, from sales to transportation, always follow the specific standards requested by our customers. As a professional rubber extrusion supplier, we continuously improve our internal procedures. We do this to meet the needs of our customers and partners at home and abroad.

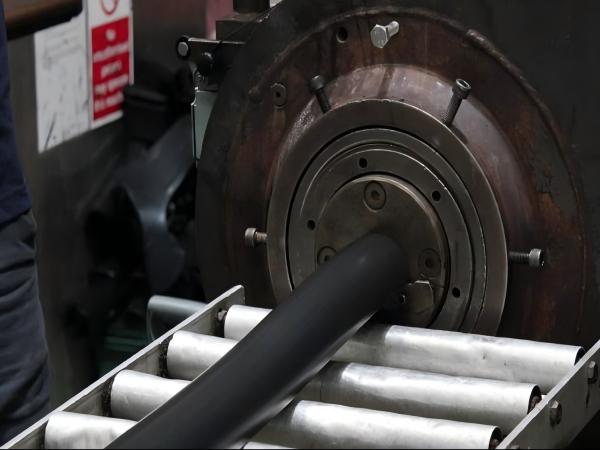

Rubber extrusion is a process of turning rubber materials into a shaped product. It involves compounding, heating, kneading, pressurizing, extrusion, and vulcanizing. Rubber extrusion manufacturers use rubber extruder machinery to make the shaped product possible. The rubber extruder machinery consists of a heated shearing screw conveyor and a die.

The raw rubber material is processed through the screw, by which the feedstock is pushed while it is heated up in the conveying channel. The feedstock is sent to the conveyor through the hopper, where it is softened by heating and shearing and pressurized by the rotation of the screw. The pressurized feedstock is then pushed into the die at the end of the extruder machinery, where the shaped product is formed and finished.

Rubber extrusion products are widely used in many industries. They are known for being versatile, durable, and easily shaped into complex designs. okin Rubber, a trusted rubber extrusion manufacturer, offers high-quality, affordable products globally. Our extruded rubber seals are commonly used in the following applications:

Rubber extrusions are suitable for the automotive sector for door seals, window seals, trunk seals, and engine gaskets. They can help reduce noise, prevent water and dust ingress, and improve overall vehicle performance.

Rubber extrusions are ideal for the construction industry’s window seals, door seals, expansion joints, and weather stripping. They play a crucial role in insulation, energy savings, and waterproofing.

Rubber extruded seals have excellent electrical insulation properties, making them good insulators for wires and cables. They’re used to protect cables from environmental factors for enhanced safety.

In aerospace, rubber extrusions can be used to seal the gaps around windows and fuel tanks. They can withstand extreme temperatures and pressures, providing excellent flexibility and durability.

The marine industry uses rubber extrusions for hatch, door, and window seals. They are designed to withstand harsh marine environments and prevent moisture from entering the cabin and seawater corrosion.

Rubber extrusions are also used in medical devices and equipment, such as tubing, gaskets, and seals. These applications need high-quality, medical-grade rubber that is safe for use in medical environments.

Rubber extrusions made from food-grade materials are used for seals, gaskets, and hoses in applications that come into direct contact with food and beverages. The extrusions must meet stringent hygiene and safety standards.

Rubber seal extrusion profiles can be manufactured into a variety of different cross-sectional shapes. Such as round, square, rectangular, U-shaped, T-shaped, etc., to adapt to different projects and environments.

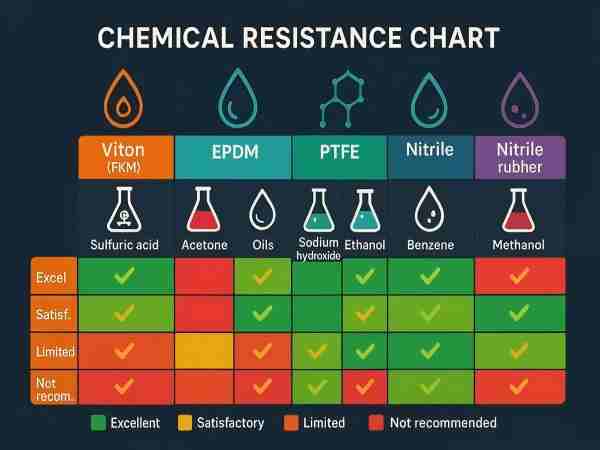

Rubber seal extrusion profiles can be used in harsh chemical environments. They are not susceptible to corrosion damage.

Extruded rubber products can return to their original shape after deformation. It is suitable for applications requiring sealing, waterproofing, shock absorption, cushioning, etc.

Rubber extrusion profiles have good anti-oxidation and anti-ultraviolet aging properties. It can be used for a long time in indoor and outdoor environments without failure.

Extruded rubber sealing strips can be used to manufacture seals. Such as sealing strips, sealing rings, etc., to ensure the sealing performance of mechanical equipment, doors and windows, etc.

Extruded rubber products are made of environmentally friendly materials and meet environmental standards. It reduces the impact on the environment.

Advanced rubber extrusion machinery allows us to manufacture a vast range of rubber extrusion profiles. They can meet different standards and specifications required by customers in different industries. If your project requires a specific design, size, or function, then Okin Rubber can provide custom options to meet your needs.

A reputable manufacturer should have a robust quality control process. okin Rubber can ensure our extruded rubber seals meet industry standards and customer specifications. A highly skilled team can produce custom rubber extrusions based on specific specification samples or drawings. We can meet the exact requirements of our discerned customers.

Superior rubber extrusion manufacturing technology makes it possible to reduce the waste of rubber materials used. It can save the expenditure on the whole manufacturing process. So, we can supply a wide array of extruded rubber seals and profiles with high quality and affordable prices.

The shipping and logistics selected vary depending on the weight and dimensions of the goods. Normally we will deliver orders by air service and send you a notice before the order is shipped out. Such as DHL, UPS, FedEx, or other express designated by customers. Once the goods are shipped, we will let you know the tracking number. You can track the shipment status every step of the way. After you receive the order, please check the goods first to ensure they are in perfect condition. If the goods are unfortunately damaged or broken, please feel free to contact us.

Rubber extrusion is a manufacturing process that produces continuous lengths of rubber with specific shapes. Raw rubber is heated, softened, and pushed through a die to form seals, pipes, and profiles.

The minimum order quantity is typically 500 meters, though it may vary based on specifications. Contact us for details.

We offer all-in-one solutions including custom extrusion based on samples/drawings, installation advice, cutting, and maintenance support.