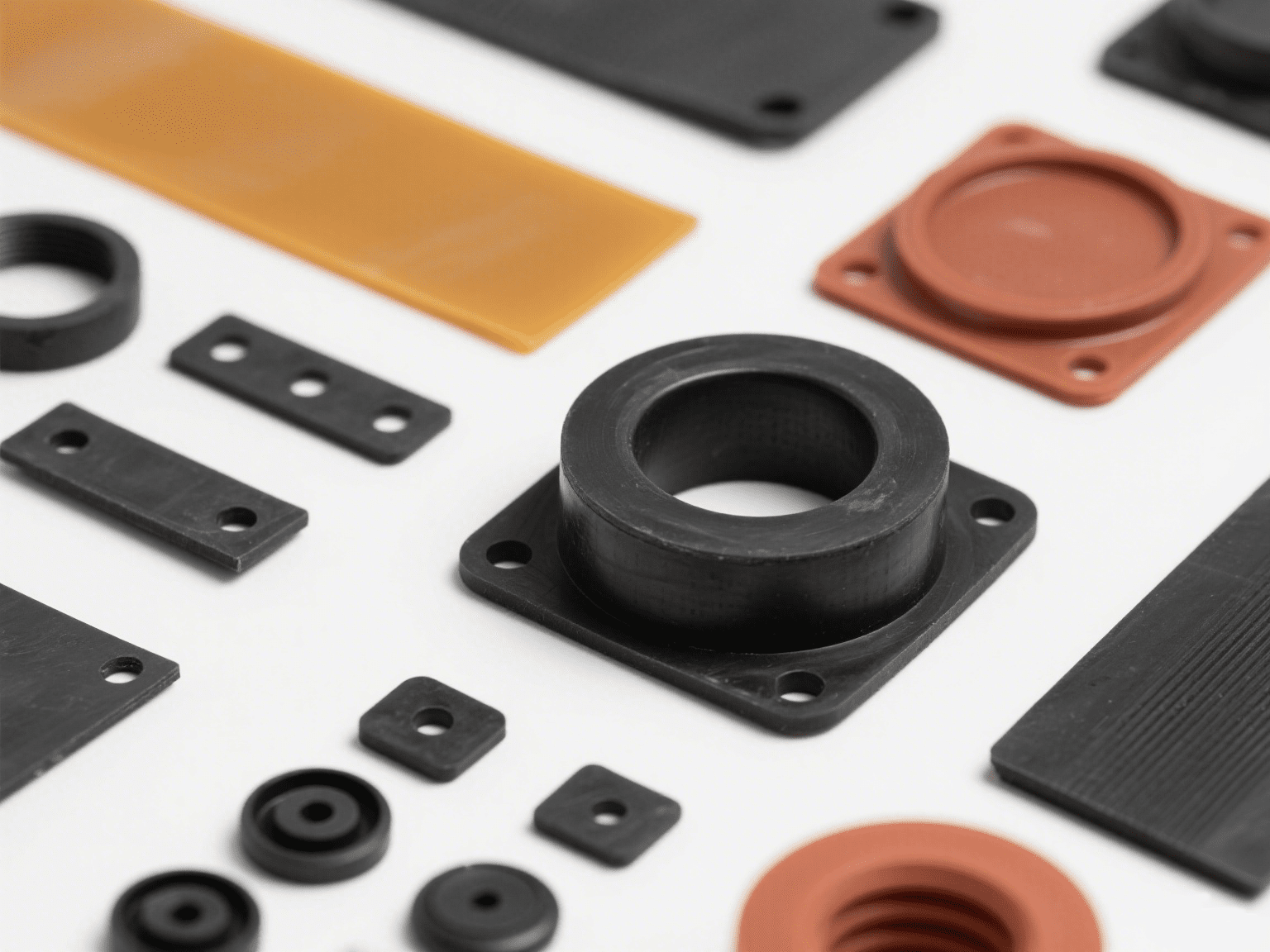

Rubber Molding is a precision manufacturing process used to produce high-performance rubber components with complex three-dimensional geometries. Compared with other methods like extrusion, molded rubber parts offer superior dimensional accuracy, tighter tolerances, and enhanced physical properties. They are ideal for demanding applications such as sealing, vibration isolation, insulation, fluid control, and structural support. Molded rubber products play a critical role across industries, including automotive, aerospace, electrical, HVAC, medical, marine, and heavy industrial equipment.

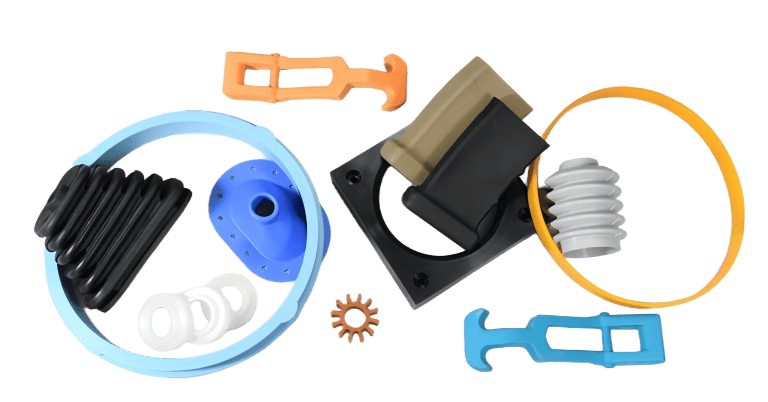

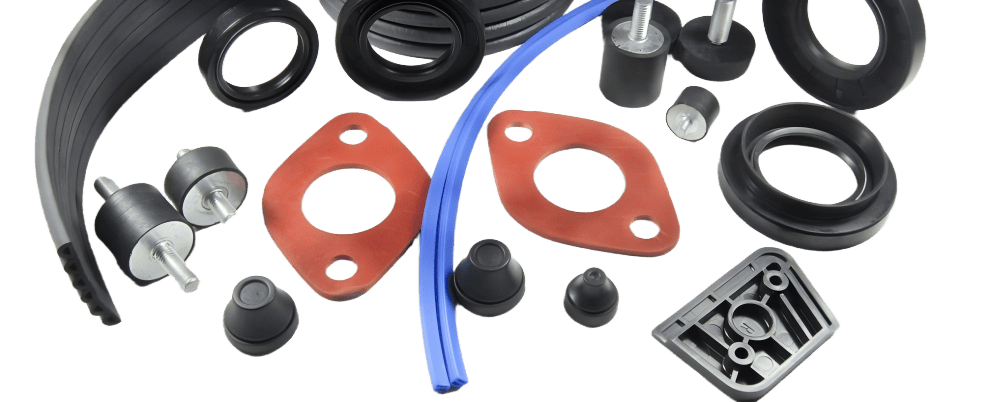

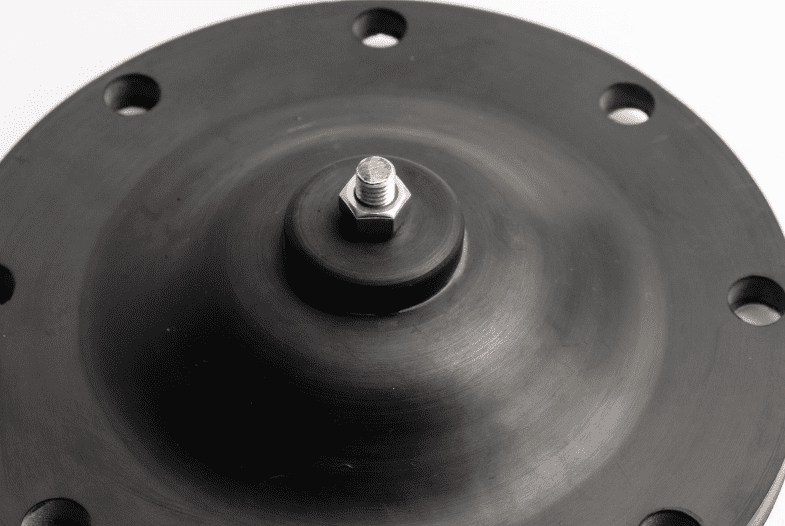

Okin Seal is a professional rubber molded parts manufacturer offering customized molded rubber components tailored to your specific needs. We specialize in compression molding, injection molding, and transfer molding techniques to produce rubber parts with high durability and optimal performance. Our molded rubber product range includes rubber gaskets, seals, bushings, bellows, diaphragms, O-rings, vibration mounts, boots, caps, and custom OEM rubber parts made of EPDM, NBR, Silicone, Neoprene, SBR, FKM, and more.

View All ⇊

With over 20 years of experience, Qingdao Okin Industrial Co., Ltd. is a trusted manufacturer of molded rubber components in China. Our facility is equipped with state-of-the-art rubber injection machines, automated molding presses, and in-house mold design capabilities using CAD/CAM systems. We support both small-batch prototyping and large-scale production.

All products are manufactured under strict quality control systems and comply with ISO, RoHS, and REACH standards. Our skilled team of engineers ensures every molded rubber component meets precise dimensional and performance requirements. From automotive sealing systems to precision medical gaskets, we provide stable quality, reliable delivery, and responsive customer service.

Okin Seal has passed ISO9001, IATF 16949, and ROHS/REACH certifications, which ensure our molded rubber parts meet international quality and environmental standards. Our factory is equipped with a full set of internal testing equipment including tensile strength testers, aging chambers, hardness testers, and 2D/3D measuring systems.

We establish detailed SOPs for each production process — from raw material inspection to final product packaging. Each batch of molded parts is traceable and undergoes 100% inspection for critical dimensions and defects. We also provide PPAP, IMDS, or other documents for automotive and industrial projects.

As one of the leading rubber molded parts suppliers in China, we are committed to continuous quality improvement and long-term reliability in every order we fulfill.

Rubber molding typically involves the following steps:

Rubber molded parts are critical components used across a wide range of industries. They are valued for their excellent sealing capabilities, dimensional stability, and resistance to harsh environments. With the ability to be molded into highly complex shapes and custom geometries, molded rubber products offer unmatched performance in both static and dynamic applications. As a reliable manufacturer of custom rubber molded components, Okin Seal provides high-quality, cost-effective molded rubber solutions to global customers. Our molded rubber parts are commonly used in the following industries and applications:

Used for gaskets, mounts, seals, bellows, boots, and bushings in engines, transmissions, suspension, and HVAC systems.

Rubber molded insulators, switch boots, and grommets ensure safe and reliable electrical protection.

Medical-grade rubber seals, diaphragms, and stoppers are used in pumps, diagnostic equipment, and surgical tools.

Lightweight yet durable molded parts are used for sealing, insulation, and vibration damping in aircraft systems.

Rubber gaskets and seals are essential in heating, cooling, and fluid distribution systems.

Custom rubber components support motion control, fluid sealing, and machine protection.

Resilient rubber parts offer saltwater resistance and long-term durability for marine environments.

Capable of producing 3D shapes and fine surface details not possible with extrusion.

Ensures high-precision parts with repeatable tolerances.

Wide selection of elastomers with specific resistances to oil, heat, abrasion, etc.

High strength-to-weight ratio, ideal for dynamic or load-bearing environments.

Advanced bonding between rubber and inserts improves mechanical strength.

Tailored to customer designs, including prototyping and tooling support.

Our state-of-the-art rubber molding technology enables us to produce a wide variety of rubber molded parts that meet diverse industry standards and customer specifications. Whether you need complex geometries, unique material formulations, or special performance attributes, Okin Seal can deliver fully customized solutions tailored to your project needs.

At Okin Seal, we prioritize quality and precision in every molded rubber product we manufacture. Our rigorous quality control processes ensure that each rubber molded part meets or exceeds industry standards. With our skilled team and advanced machinery, we can bring your designs to life with unmatched accuracy and consistency.

Thanks to our efficient molding technology and optimized production processes, we are able to minimize material waste and enhance production efficiency. This allows us to provide high-quality rubber molded parts at highly competitive prices, ensuring excellent value for our customers without compromising on quality.

We provide efficient and secure shipping solutions for our rubber molded parts. Our logistics team ensures that every order is handled with care, using trusted carriers such as DHL, UPS, FedEx, and others. We prioritize timely delivery and maintain communication throughout the shipping process.

Rubber molding is a process where raw rubber material is shaped into specific forms using heat and pressure.

Yes, we provide custom solutions based on your specifications, including size, drawing, material, guidance and application requirements.

Our products are used in automotive, construction, aerospace, marine, electrical, medical, and food processing industries.

Lead time varies depending on the product complexity and order volume. Generally, it takes about 2-4 weeks.