OKIN Seal manufactures high-performance EPDM rubber seals designed to provide superior air, dust, and watertight sealing for industrial and commercial applications. Our profiles feature excellent compression set recovery, ensuring they maintain a tight seal even after years of compression and exposure to harsh elements.

Performance Characteristics

Common Profiles

View All ⇊

We implement rigorous quality control protocols across all our solid and sponge EPDM profiles. By strictly utilizing premium virgin raw materials, we guarantee our extruded rubber sealing strips offer superior resistance to wear, aging, and chemical corrosion, ensuring a prolonged service life.

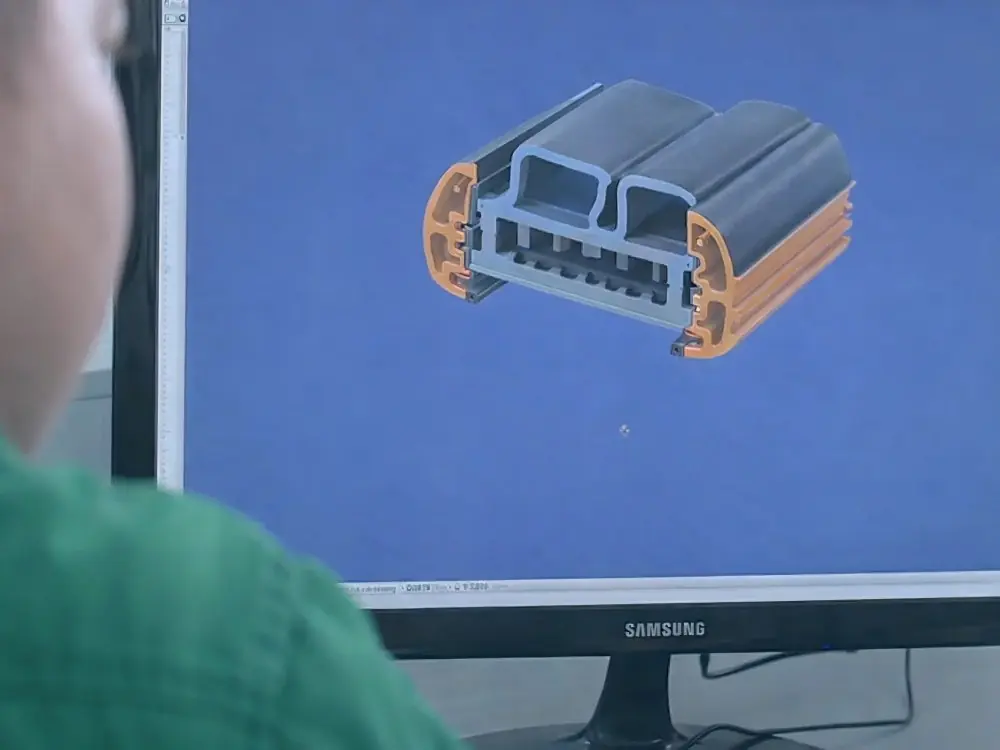

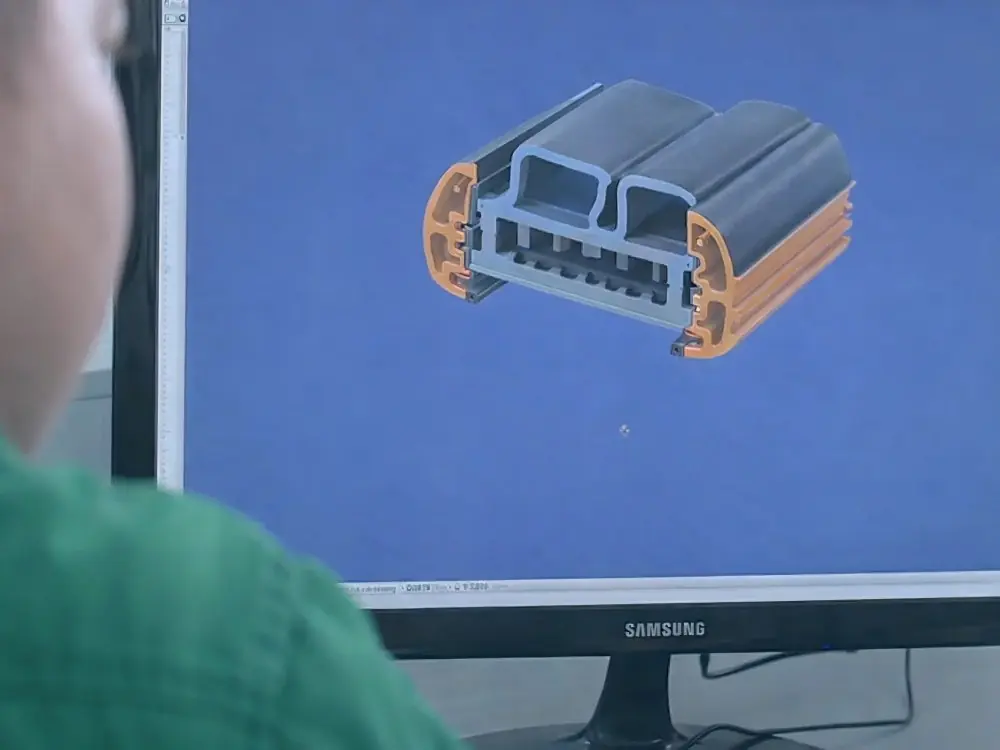

As a dedicated source factory, we specialize in OEM custom EPDM rubber seals mapped exactly to your CAD drawings. We support rapid tooling development for various complex cross-sections and offer precise hardness adjustments to match specific industrial application requirements.

Our facility is equipped with state-of-the-art microwave vulcanization lines and continuous extrusion technology. This allows us to process high-precision rubber components with extreme dimensional stability, giving you a competitive edge with rapid lead times and strictly on-time delivery.

Our custom EPDM rubber seals are the primary choice for automotive, construction, and industrial applications. They are widely used as window and door seals, protective weatherstripping, and electrical enclosure gaskets. Additionally, our solid and sponge extrusions are frequently employed in HVAC systems for drain tubes, compressor vibration dampeners, and insulation purposes.

Our extrusion facility manufactures a wide variety of standard and custom EPDM rubber profiles, including:

D-sections, P-sections, U-channels, O-ring cords, square, and rectangular shapes. To facilitate fast assembly, most of our extruded sealing strips can be laminated with high-adhesion PSA (Pressure Sensitive Adhesive) backing.

Thanks to its outstanding resistance to UV radiation, ozone, and extreme weather, a high-quality EPDM rubber seal can easily last between 20 to 50 years depending on the application environment. At OKIN, we use 100% virgin rubber to ensure our extruded profiles maintain their elasticity and sealing performance over decades of use.

While EPDM is excellent against water, steam, and mild chemicals, it is generally not compatible with petroleum-based oils, mineral oils, gasoline, and hydrocarbon solvents. If your sealing project involves direct contact with fuels or heavy oils, we recommend customizing our NBR (Nitrile) or FKM rubber seals instead.

Neither is strictly "better"—it depends on your application. EPDM is highly cost-effective and superior for outdoor applications requiring excellent weather, UV, and abrasion resistance (like automotive weatherstripping). Silicone is preferable if your project demands extreme high-temperature resistance (above 150°C/300°F) or FDA food-grade compliance. OKIN can expertly extrude both materials based on your drawings.

As an IATF 16949 certified factory, we offer rapid and reliable turnaround times. Custom tooling and initial sample development typically take 7-10 days after CAD drawing approval. For mass production of solid or sponge extrusions, our standard lead time is 15-25 days, depending on the volume and profile complexity.

We implement rigorous quality control measures to ensure consistent excellence across our EPDM, foam, and sponge rubber seals. Manufactured from premium raw materials, our profiles offer superior resistance to wear, aging, and corrosion, guaranteeing strong, durable performance.

As a professional EPDM rubber seal manufacturer, we can provide customized EPDM sealing strips to meet customers’ specific requirements. We have a lot in stock. The models are complete and the scope of application is wider. We can customize it according to the size you want.

Our company is equipped with advanced manufacturing equipment and technology. So, we are in a position to manufacture high-quality EPDM rubber strips. We can offer custom products according to customer’s requirements, samples, and drawings. This gives us an edge on the lead time and on-time delivery.

EPDM rubber seal has been the primary choice for automotive, construction, and industrial applications. Such as window and door seals, protective pads, and electrical gaskets for sealing and insulation purposes. It is also employed in HVAC machinery (heating, ventilation, and air conditioning) as the drain tube, compressor gaskets, pressure switch tubing, etc.

The most common types of EPDM rubber seals on the market include:

D-section, P-section, U-channel, o-ring cord, square-shaped, rectangle-shaped, door and window seals. Most of them can be provided with a self-adhesive finish.

EPDM Rubber (Ethylene Propylene Diene Monomer rubber) is a synthetic rubber. It is made of three components. They are ethylene, propylene, and diene monomer. EPDM Rubber is durable and flexible and is used widely in various applications.

EPDM Rubber can work under extensive temperatures ranging from -50℃ to +150℃.

We focus on on-time delivery. Your order will be handled within 24 hours, put into production asap, and shipped out by air freight. The delivery time may vary depending on the order sequence.