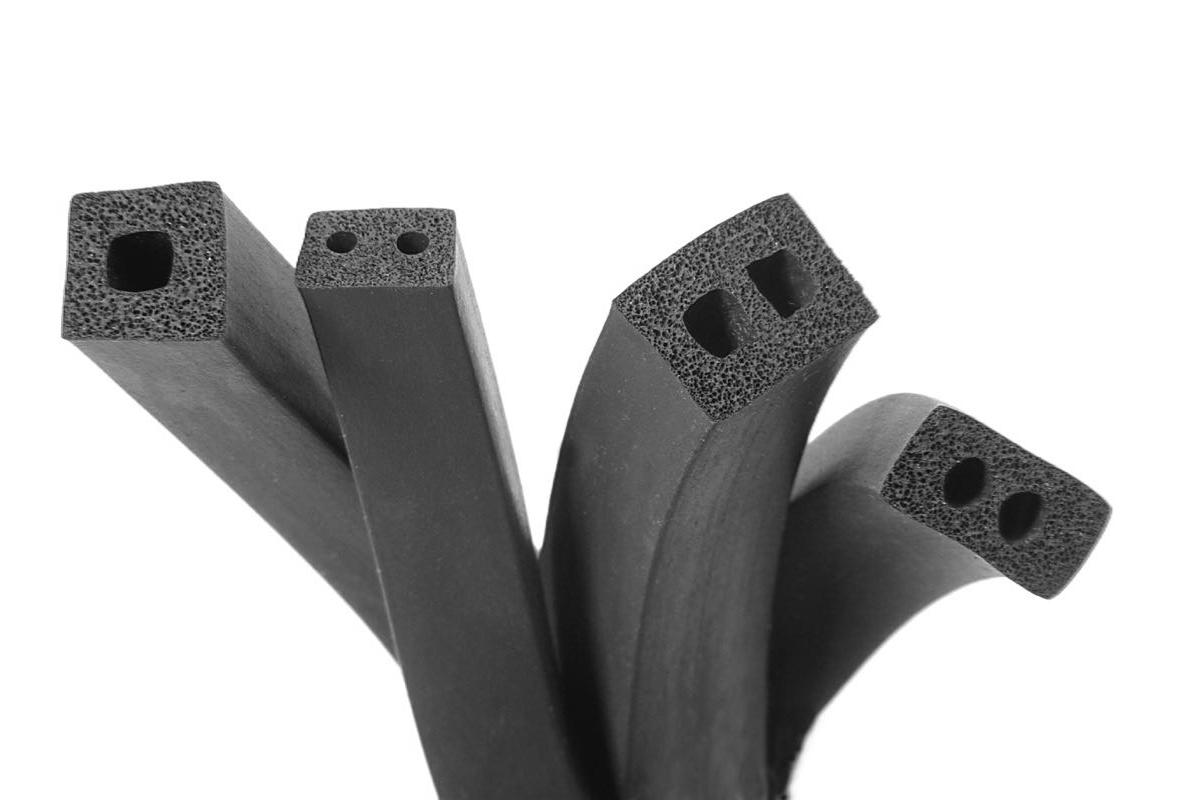

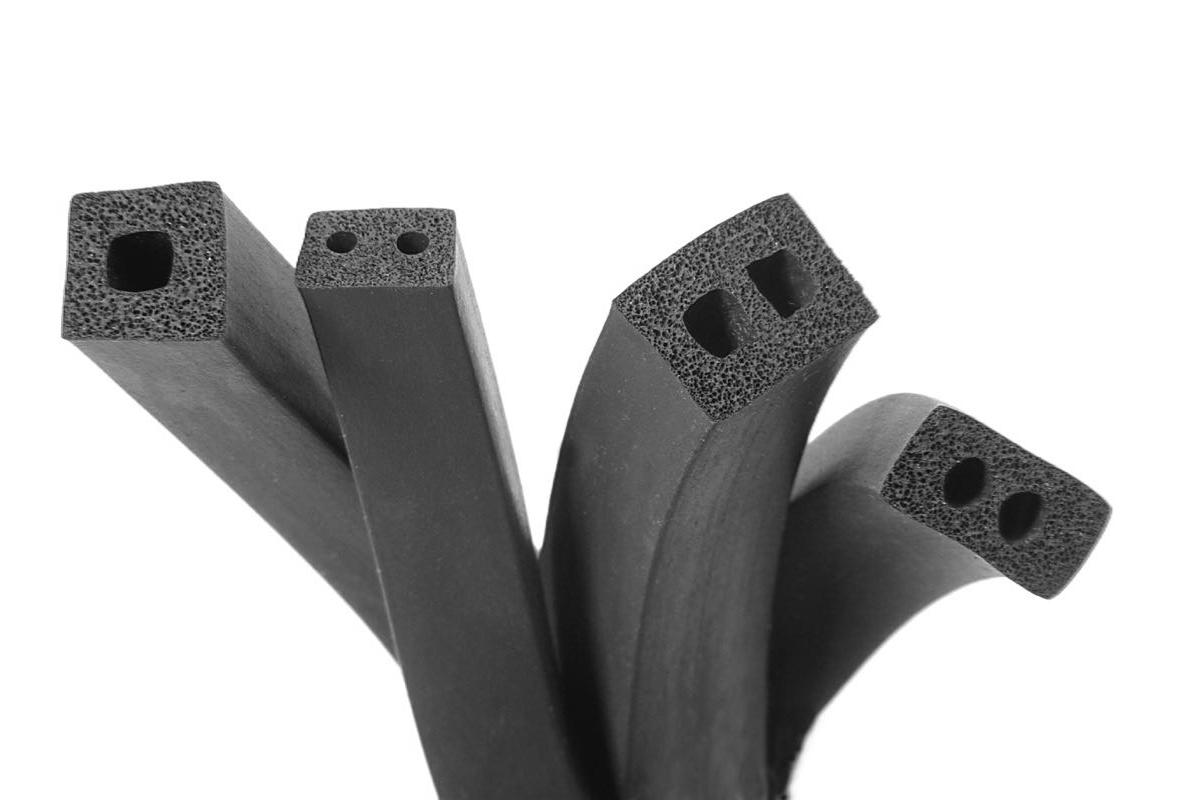

Foam seal refers to continuously extruded rubber profiles with a cellular, sponge-like structure that deliver exceptional lightness, high compressibility, and superior cushioning properties. They are classified into two main categories based on cell morphology:

View All ⇊

Foam rubber extrusion creates a cellular structure with interconnected air or gas-filled cells. It can provide cushioning, flexibility, and compressibility.

Foam rubber exhibits excellent compression and recovery properties. So it can compress under pressure and quickly regain its original shape after release.

Foam rubber profiles offer inherent thermal and acoustic insulation properties. It can reduce heat transfer and sound transmission.

Foam rubber profiles are highly flexible and conform to irregular surfaces or contours. It can ensure proper fit and sealing.

Foam rubber exhibits resistance to moisture, water absorption, and certain chemicals. It is suitable for humid or wet environments and contact with certain substances.

The foam or sponge rubber profiles suit various. Industries and applications, including automotive, construction, HVAC, electronics, packaging, and more. They are used for sealing applications (gaskets and weatherstripping), insulation, cushioning, soundproofing, shock absorption, and vibration dampening.

Foam rubber extrusions are commonly made of neoprene, EPDM (ethylene propylene diene monomer), silicone, and polyurethane. When selecting the material, it depends on the properties. Such as density, hardness, temperature, and chemical resistance.

The working temperature of foam rubber extrusion depends on the specific type of rubber material used in the manufacturing process. Here are the approximate working temperature ranges for some used foam rubber materials:

Foam rubber extrusion creates a cellular structure with interconnected air or gas-filled cells. It can provide cushioning, flexibility, and compressibility.

The density and hardness of foam rubber profiles can be tailored to meet specific application requirements.

Foam rubber exhibits excellent compression and recovery properties. So it can compress under pressure and quickly regain its original shape after release.

Foam rubber profiles offer inherent thermal and acoustic insulation properties. It can reduce heat transfer and sound transmission.

Foam rubber profiles are highly flexible and conform to irregular surfaces or contours. It can ensure proper fit and sealing.

Foam rubber exhibits resistance to moisture, water absorption, and certain chemicals. It is suitable for humid or wet environments and contact with certain substances.

The foam or sponge rubber profiles suit various. Industries and applications, including automotive, construction, HVAC, electronics, packaging, and more. They are used for sealing applications (gaskets and weatherstripping), insulation, cushioning, soundproofing, shock absorption, and vibration dampening.

Foam rubber extrusions are commonly made of neoprene, EPDM (ethylene propylene diene monomer), silicone, and polyurethane. When selecting the material, it depends on the properties. Such as density, hardness, temperature, and chemical resistance.

The working temperature of foam rubber extrusion depends on the specific type of rubber material used in the manufacturing process. Here are the approximate working temperature ranges for some used foam rubber materials: