Custom Formula R&D Capabilities

Our in-house laboratory specializes in developing custom rubber formulations to meet specific ASTM, SAE, and ISO standards. We strictly use 100% virgin materials (RoHS/REACH compliant) to ensure optimal performance. Custom compounding options include UL94 Flame Retardant, High-Conductivity, and Extreme Temperature Resistance.

Rubber Material

EPDM Rubber

Temperature Range: -40°C to +150°C

Key Properties: Excellent weather, Ozone, and UV resistance. Superior resistance to steam and water. High elasticity with low compression set.

Best For: Outdoor sealing strips, automotive weatherstrips, window gaskets, and marine applications.

CR Rubber

Temperature Range: -40°C to +100°C

Key Properties: Balanced performance. Good resistance to oils, chemicals, and weathering. Inherently flame retardant (self-extinguishing).

Best For: General-purpose seals, HVAC gaskets, and flame-retardant applications.

NBR

Temperature Range: -30°C to +120°C

Key Properties: Excellent oil and fuel resistance. Good mechanical properties and abrasion resistance.

Limitations: Poor resistance to Ozone and sunlight (not recommended for direct outdoor exposure).

Best For: Fuel system seals, oil hoses, and machinery gaskets.

Natural Rubber(NR)

Temperature Range: -50°C to +70°C

Key Properties: Outstanding elasticity and abrasion resistance. Exceptional tensile strength and vibration dampening capabilities.

Best For: Vibration isolators, shock mounts, and heavy-duty dynamic parts.

Silicone Rubber

Temperature Range: -60°C to +230°C

Key Properties: Extreme temperature flexibility. Non-toxic, odorless, and chemically inert. Excellent UV and color stability.

Best For: High-temperature seals, food/medical grade applications, and aesthetic parts.

Plastic Material

TPE (Thermoplastic Elastomer)

Temperature Range: -40°C to +135°C

Key Properties: Eco-friendly and Recyclable. Combines the processing advantages of plastics with the elasticity of rubber. Easy to color-match.

Best For: Automotive window encapsulation, consumer grips, and recyclable sealing profiles.

PVC (Polyvinyl Chloride)

Temperature Range: -20°C to +70°C

Key Properties: Cost-effective. Good chemical resistance and inherent flame retardancy. High rigidity options available.

Best For: Economic edge trims, door bottoms, and rigid-flexible co-extrusions.

Precision Extrusion Technology

Our advanced polymer extrusion lines are designed to produce complex profiles with tight tolerances. Whether you need solid, sponge, or dual-durometer (co-extruded) profiles, we can process a wide range of materials including EPDM, NBR, CR, and Silicone. Instead of standard “off-the-shelf” products, we specialize in custom-engineered profiles that offer superior sealing performance and durability.

Microwave Vulcanization & Curing

We utilize state-of-the-art Microwave Curing Systems and High-Velocity Hot Air tunnels to ensure uniform vulcanization from the inside out. Unlike traditional methods, this continuous process guarantees a smoother surface finish, higher dimensional stability, and rapid production speeds for high-volume orders. Our process is optimized to prevent porosity and ensure consistent physical properties across every meter of the sealing strip.

Value-Added Fabrication Services

Our capabilities go beyond basic extrusion. With our dedicated finishing workshop, we transform profiles into “ready-to-install” components.

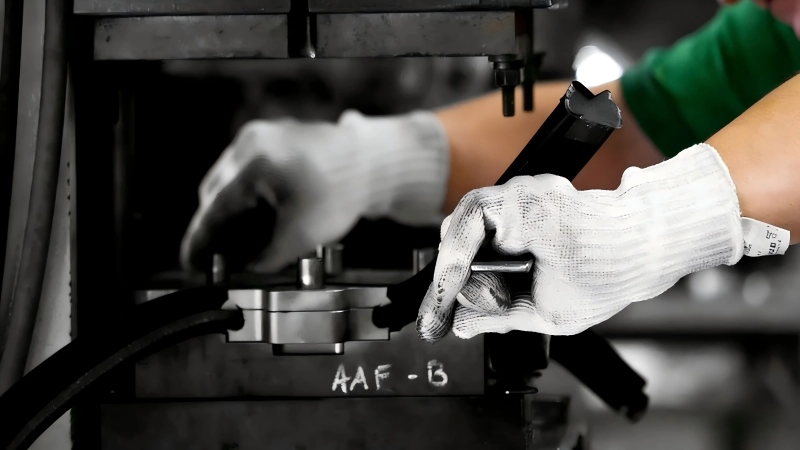

Hot Vulcanized Splicing: (As shown) We utilize precision molding presses to create seamless, high-strength bonded corners. This ensures 100% water and air tightness at critical joints.

Custom Detailing: We offer precision cutting, drilling, and notching services to meet exact assembly requirements.

Adhesive Taping: Application of pressure-sensitive adhesive (PSA) tapes (e.g., 3M, Sony) for easy peel-and-stick installation

Manufacturing Tolerance

We strictly adhere to international dimensional standards to ensure seamless assembly. While our standard production follows DIN ISO 3302-1 Class E2 (Solid) and E3 (Sponge), we are capable of achieving tighter tolerances (Class E1) for critical automotive applications upon request.

Solid Rubber Profiles – Tolerances based on DIN ISO 3302-1 Class E2

| Nominal range in mm | +/- mm | ||

|---|---|---|---|

| ≤ | 1.5 | 0.25 | |

| 1.5 | to | 2.5 | 0.35 |

| 2.5 | to | 4 | 0.4 |

| 4 | to | 6.3 | 0.5 |

| 6.3 | to | 10 | 0.7 |

| 10 | to | 16 | 0.8 |

| 16 | to | 25 | 1 |

| 25 | to | 40 | 1.3 |

| 40 | to | 63 | 1.6 |

| 63 | to | 100 | 2 |

Sponge Rubber Profiles – Tolerances based on DIN ISO 3302-1 Class E3

| Nominal range in mm | +/- mm | ||

|---|---|---|---|

| ≤ | 1.5 | 0.4 | |

| 1.5 | to | 2.5 | 0.5 |

| 2.5 | to | 4 | 0.7 |

| 4 | to | 6.3 | 0.8 |

| 6.3 | to | 10 | 1 |

| 10 | to | 16 | 1.3 |

| 16 | to | 25 | 1.6 |

| 25 | to | 40 | 2 |

| 40 | to | 63 | 2.5 |

| 63 | to | 100 | 3.2 |

Sponge Rubber Profiles – Tolerances based on DIN ISO 3302-1 Class E3

| Nominal range in mm | +/- mm | ||

|---|---|---|---|

| ≤ | 6.3 | 0.5 | |

| 6 | to | 10 | 0.7 |

| 10 | to | 16 | 0.8 |

| 16 | to | 25 | 1 |

| 25 | to | 40 | 1.3 |

| 40 | to | 63 | 1.6 |

| 63 | to | 100 | 2.0 |

| 100 | to | 160 | 2.5 |

| 160 | to | 63 | 1.5% |

Cut Length Tolerances – Based on DIN ISO 3302-1 Class L3

| Nominal range in mm | +/- mm | ||

|---|---|---|---|

| ≤ | 40 | 1.6 | |

| 40 | to | 63 | 2 |

| 63 | to | 100 | 2.5 |

| 100 | to | 160 | 3.2 |

| 160 | to | 250 | 4 |

| 250 | to | 400 | 5 |

| 400 | to | 630 | 6.3 |

| 630 | to | 1000 | 10 |

| 1000 | to | 1600 | 12.5 |

| 1600 | to | 2500 | 16 |

| 2500 | to | 4000 | 20 |

| 4000 | to | 0.005 | |

Cut Length Tolerances – Based on DIN ISO 3302-1 Class L3

| Nominal range in mm | +/- mm | ||

|---|---|---|---|

| ≤ | 3 | 0.4 | |

| 3 | to | 6 | 0.6 |

| 6 | to | 10 | 0.7 |

| 10 | to | 18 | 0.8 |

| 18 | to | 30 | 1 |

| 30 | to | 50 | 1.2 |

| 50 | to | 80 | 1.5 |

| 80 | to | 120 | 1.9 |

| 120 | to | 180 | 2.3 |

| 180 | to | 250 | 2.8 |

| 250 | to | 320 | 3.5 |

| 320 | 1.4% | ||

Cut Length Tolerances – Based on DIN ISO 3302-1 Class L3

| Nominal range in mm | +/- mm | ||

|---|---|---|---|

| ≤ | 400 | 5 | |

| 400 | to | 1000 | 10 |

| 1000 | to | 2500 | 20 |

| 2500 | to | 6000 | 30 |

| 6000 | to | 2% | |