In concrete construction, preventing water leakage through joints and gaps is critical. That’s where waterstops come in. Among various types, Rubber Waterstops and PVC Waterstops are the most commonly used. Understanding their differences can help you select the right material for your project, ensuring long-term durability and performance.

Quick Comparison Table

| Feature | Rubber Waterstop | PVC Waterstop |

| Material | Natural & synthetic rubber | Polyvinyl chloride (PVC) |

| Flexibility | High | Moderate |

| Temperature Resistance | Limited at low temperatures | Excellent |

| Corrosion Resistance | Moderate | Excellent |

| Durability | High | Very High |

| Cost | Higher | Lower |

| Application | Irregular surfaces, flexible joints | Straight joints, low-temp areas |

What is Rubber Waterstop?

Rubber Waterstop is a flexible construction element designed to seal joints in concrete structures and prevent water penetration.

Common Types:

- Buried Rubber Waterstop

- External Rubber Waterstop

- CB/CP/EP/EB type profiles

Key Advantages:

- Excellent flexibility, adapts to irregular surfaces

- Good watertightness and chemical resistance

- Suitable for high-movement joints

Limitations:

- Poor performance under very low temperatures

- Moderate corrosion resistance compared to PVC

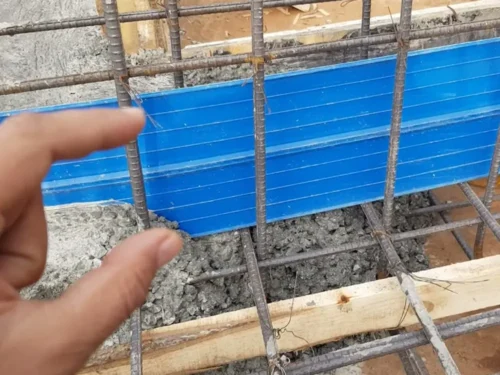

What is PVC Waterstop?

PVC Waterstop is another popular choice made from durable, flexible polyvinyl chloride, designed to accommodate structural movement while preventing water ingress.

Common Types:

- Dumbbell Waterstop

- Ribbed Waterstop

- Base Seal and Split Waterstop

Key Advantages:

- Excellent corrosion and chemical resistance

- Outstanding low-temperature flexibility

- Longer service life (up to 40+ years)

- Lower material cost

Limitations:

- Less flexible than rubber waterstops

- Not ideal for highly irregular surfaces

Key Factors to Consider When Choosing a Waterstop

When deciding between a Rubber Waterstop and a PVC Waterstop, focus on these four major factors:

1. Material Properties

Rubber offers superior flexibility; PVC provides better corrosion and low-temperature resistance. Choose based on project environment.

2. Installation Method

- Internal Installation or External Installation affects the type of waterstop selected.

- Proper installation is critical for ensuring complete waterproofing.

3. Size and Joint Movement

The waterstop must match the size of the concrete joint and accommodate expected movement.

4. Application Environment

Exposure to chemicals, temperature extremes, or structural movement will guide your material choice.

FAQs About Rubber Waterstop vs PVC Waterstop

Q: What types of waterstops are available?

A: Rubber waterstops, PVC waterstops, metal waterstops, and bentonite waterstops. Rubber and PVC types are the most widely used.

Q: Which one is better, Rubber or PVC Waterstop?

A: It depends. Rubber is best for flexibility; PVC is best for corrosion and cold resistance.

Q: How long does a PVC Waterstop last?

A: Properly installed PVC waterstops can last over 40 years.

Q: What is the difference between TPV and PVC Waterstop?

A: TPV combines rubber and plastic properties, offering higher flexibility than standard PVC.

Conclusion

Choosing the right waterstop is critical for effective construction joint sealing and water leakage prevention.

- For high flexibility and adaptability on irregular surfaces, choose Rubber Waterstops.

- For superior corrosion resistance, lower cost, and longer service life, choose PVC Waterstops.

Need help selecting the right waterstop for your project? Contact Okin Rubber’s experts today!