Introduction

In global B2B logistics, shipping containers are the backbone of sea, rail, and road transport. Yet harsh weather—wind-driven rain, dust ingress, and moisture—threatens the integrity of your cargo. Premium container door seals create an airtight barrier against water, dust, air, and contaminants, ensuring your goods arrive intact. This guide covers everything from seal fundamentals and popular profiles to step‑by‑step replacement instructions.

What Are Container Door Seals?

Definition

Container door seals—also called container gaskets or weather stripping—are flexible profiles mounted on door edges to close gaps between the door frame and panel.

Material

EPDM (Ethylene Propylene Diene Monomer) delivers exceptional weather, UV, ozone, and temperature resistance (−40 °C to 120 °C), making it the industry standard for outdoor sealing.

Why Seal Installation Is Critical

- Water & Dust Protection

Shields cargo from rain, salt spray, and dust to prevent corrosion and contamination. - Temperature Control

Creates airtight insulation for reefer containers, boosting cooling efficiency and reducing energy costs. - Leak Prevention

Secures liquid, gas, or powder loads by sealing joints, eliminating environmental and safety risks. - Extended Service Life

Flexible seals reduce wear on metal hinges and frames, prolonging container durability.

Popular Seal Profiles

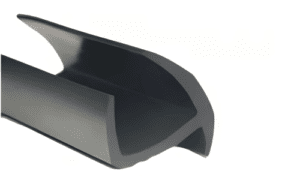

J‑Type Seal

- Cross‑section shaped like the letter “J.”

- Withstands high compression (up to 10 MPa).

- Operates reliably from −40 °C to 120 °C.

- Ideal for standard dry and refrigerated containers.

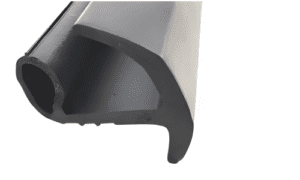

U‑Shape Profile

- U‑shaped channel grips door edge.

- Flat base allows secure attachment.

- Easy to install and remove for maintenance.

H‑Shape Seal

- Dual‑lip design for superior airtightness.

- Excellent resistance to mechanical stress.

- Recommended for high‑risk leak scenarios.

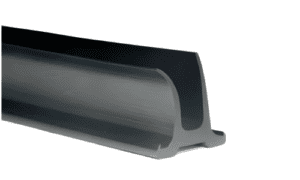

Edge Seal with Hole

- Integrated bolt holes for mechanical fastening.

- Ensures firm fixation under heavy loads.

- Perfect for high‑security or hazardous cargo containers.

Step‑by‑Step Replacement

1. Preparation & Inspection

Identify cracks, hardening, or deformation in the existing seal. Mark areas that require replacement.

2. Remove Old Seal

Use a sharp blade or cutting tool to slice through the damaged section. Clean away old adhesive and debris to ensure proper bonding.

3. Cut New Seal

Measure door perimeter, adding 2–3 mm extra length. Trim the EPDM seal with a precision knife—avoid undersizing.

4. Install & Fasten

Press the seal into its channel. Where applicable, insert bolts or rivets through pre‑punched holes. Apply industrial adhesive evenly along the contact surface.

5. Final Inspection

Close the door and perform a water spray or air‑leak test. Confirm no gaps or leaks remain.

Conclusion

Container door seals are critical components that protect your cargo from weather, contamination, and leaks. OKIN’s advanced extrusion capabilities and premium EPDM formulations ensure you receive industry‑leading performance and reliability. Partner with OKIN to secure your supply chain—every seal, every shipment.