An edge trim is an essential component used across many industries to protect and enhance the edges of materials like car doors, windows, sheet metal, and more. Without proper edge protection, exposed edges become vulnerable to damage, wear, and corrosion.

In this article, we will explore the different types of edge trims, the materials they are made from, and how to choose the right edge trim for your project. By the end, you’ll have a clearer understanding of the key differences between rubber and plastic trims, and how each type can benefit your specific needs.

What is Edge Trim?

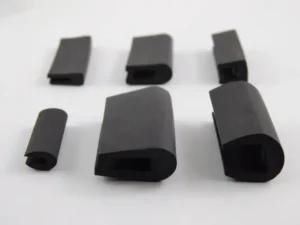

Edge trim—also known as trim seal, edge guard, or edge protector—is a flexible strip or profile designed to cover and protect exposed edges. It is commonly made from materials like rubber, plastic, vinyl, metal, or foam.

Available in a variety of shapes and sizes, edge trims are highly flexible and adaptable, making them widely used in industries such as manufacturing, construction, and automotive.

Key purposes of edge trim include:

- Covering sharp edges of metal, plastic, or glass to prevent injuries.

- Sealing the edges of car doors and windows to block water, noise, and dust.

- Enhancing the appearance of furniture and protecting delicate components in electronics.

- Providing a finished, professional look while improving safety and durability.

Choosing the right edge trim is crucial to ensuring maximum protection and functionality.

How Does Edge Trim Work?

Edge trim is typically designed as a flexible strip that fits snugly over the edge of various materials. The most common profiles include U-shape, bulb shape, and E-shape, with U-shape trims being the most widely used.

Primary functions of edge trims:

- Cushioning against impact and abrasion.

- Sealing gaps against moisture, dust, and debris.

- Improving aesthetics with a clean, finished look.

Installation is straightforward:

- Clean and dry the surface thoroughly.

- Measure and cut the trim to the required length.

- Apply adhesive or fasteners if needed.

- Press the trim firmly into place.

In many cases, trims fit tightly enough that adhesives or fasteners aren’t necessary.

Why Are Edge Trims So Important?

Although small, edge trims provide critical benefits across a wide range of industries:

- Safety: Prevents injuries caused by sharp edges.

- Aesthetics: Offers a polished, professional appearance with customizable colors and finishes.

- Protection: Extends the lifespan of materials by shielding them from wear, impact, and weathering.

- Sealing: Acts as a weatherstrip to block out moisture, dust, noise, and vibrations.

Without edge trims, products would be less safe, less durable, and less visually appealing.

Types of Edge Trim

Edge trims vary based on materials and applications. Here’s an overview:

1. Rubber Edge Trim

Often referred to as trim rubber, rubber edge molding, or rubber edge trim molding, rubber trims are highly flexible and shock-absorbent. They are typically made from:

- EPDM: Excellent resistance to weather, ozone, and UV rays.

- Neoprene: Good balance of durability and flexibility.

- NBR: Resistant to oil and chemicals.

- Silicone: High-temperature resistance and flexibility.

Best for: Automotive, industrial machinery, outdoor applications.

2. Metal Edge Protectors

Made from aluminum or stainless steel, metal trims provide unmatched durability and impact resistance but offer limited flexibility.

Best for: Heavy-duty protection in construction, industrial, and heavy machinery applications.

3. Plastic Edge Trim

Typically made from ABS or similar plastics, plastic trims are lightweight, cost-effective, and customizable in color and finish.

Best for: Indoor applications, furniture, light-duty protection.

4. Vinyl Edge Trim (PVC)

Vinyl trims, made from PVC, are moisture-resistant, UV-resistant, and flexible.

Best for: Automotive interiors, marine applications, household use.

Note: Vinyl edge trims are not suitable for high-temperature environments.

5. Foam Edge Trim

Foam trims offer excellent cushioning and are lightweight and easy to install. However, they are less durable than rubber or metal options.

Best for: Temporary or lightweight applications such as furniture and packaging.

FAQ

Q: What is an edge protector?

A: An edge protector is another term for an edge trim. It shields edges from damage and wear while improving safety and aesthetics.

Q: Is rubber edging safe?

A: Yes, rubber edging is highly safe. It cushions impacts and protects both people and surfaces from harm.

Q: How do you protect cut metal edges?

A: Using a metal edge trim or protector is the best way to safeguard sharp metal edges and prevent injury or corrosion.

Q: What is PVC edge trim?

A: PVC edge trim is made from polyvinyl chloride. It’s durable, flexible, and resistant to moisture, making it a great choice for a variety of edge-sealing applications.

Conclusion

Edge trims are essential solutions for protecting, sealing, and enhancing the appearance of materials across countless industries. Whether you need rubber, plastic, metal, vinyl, or foam trims, each material offers distinct advantages suited to different applications.

Looking for high-quality edge trim options?

We offer a wide selection of edge trims and provide custom solutions to meet your specific needs. Contact us today to find the perfect trim for your project—our team of experts is ready to assist you!