Rubber extrusion is one of the most widely used manufacturing methods in the rubber industry. While rubber molding is still applied in many situations, extrusion remains the preferred choice thanks to its high productivity, flexibility, and ability to produce durable rubber components.

At Okin Rubber, we specialize in delivering high-quality rubber extrusion services for various industries, from automotive to construction.

What is the Rubber Extrusion Process?

Rubber extrusion is a manufacturing method where rubber material is forced through a die to create continuous profiles with a consistent cross-sectional shape. Key characteristics include:

- Consistency: Produces long, uniform rubber profiles.

- Complex Shapes: Enables complex cross-sections with custom dies.

- Material Flexibility: Allows adjustment of softness and hardness.

- Ideal for Sealing: Perfect for making weatherstripping and gaskets.

Applications of Rubber Extrusion

Rubber extrusion is widely used in:

- Weatherstripping: For doors and windows.

- Tubing: For fluid and air transfer systems.

- Custom Rubber Seals: Tailored sealing solutions for various machines and equipment.

Why Choose Rubber Extrusion Over Molding?

- Cost-Effective for Long Runs: Rubber extrusion allows continuous production, reducing costs compared to individual molding processes.

- Ideal for Simple to Moderately Complex Shapes: Extrusion is perfect for seals, gaskets, and tubing, while molding is better for complex 3D shapes.

- Minimal Material Waste: The extrusion process generates very little scrap, making it more sustainable.

- Flexible Lengths and Sizes: Rubber profiles can be cut to any required length, meeting diverse project needs.

- Lower Tooling Costs: Compared to molding, extrusion requires simpler and cheaper tooling setups.

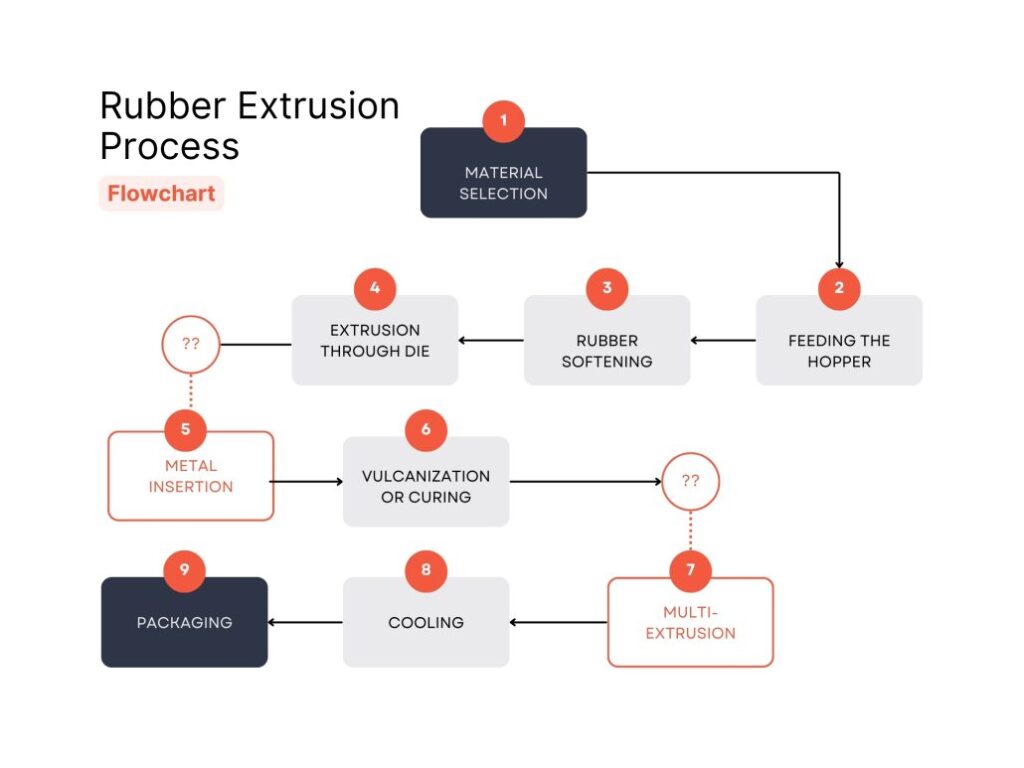

Step-by-Step Rubber Extrusion Process

Step 1: Material Selection

Choose the right rubber material based on application needs, such as silicone rubber for high temperatures.

Step 2: Feeding the Extruder

Load rubber compound into the hopper, ready for processing.

Step 3: Rubber Softening and Mixing

Rubber is softened and mixed under heat and pressure inside the extruder.

Step 4: Extrusion Through Die

Softened rubber is pushed through the die to create the desired shape.

Step 5: Metal Insertion (Optional)

For reinforced profiles, metal inserts can be embedded during extrusion.

Step 6: Vulcanization or Curing

The extruded rubber undergoes curing to achieve final strength and elasticity.

Step 7: Cooling

Profiles are cooled to stabilize their final shape.

Step 8: Cutting or Rolling

Final products are either cut to specific lengths or rolled for easier handling and shipping.

Common Rubber Materials Used in Extrusion

- Natural Rubber: High elasticity but limited chemical resistance.

- EPDM Rubber: Excellent for weather resistance and sealing.

- Neoprene Rubber: Ideal for chemical and oil resistance.

- Nitrile Rubber: Good for oil and abrasion resistance.

- Silicone Rubber: Outstanding temperature resistance from -60°C to +230°C.

Rubber Extrusion Services at Okin Rubber

As a leading rubber extrusion manufacturer, Okin Rubber offers a full range of custom rubber extrusion services, including:

- Custom Rubber Seals & Profiles

- Silicone Extrusion Solutions

- Metal-Reinforced Extrusions

- Plastic Profile Extrusion

We use only 100% virgin rubber material to ensure consistent quality and long-term durability.

Conclusion

Rubber extrusion is a highly efficient, flexible, and cost-effective process that plays a vital role across industries. Whether you need weatherstripping, tubing, or custom seals, extrusion offers significant advantages over molding.

For premium-quality rubber extrusion services tailored to your needs, contact Okin Rubber — your trusted partner in rubber innovation!