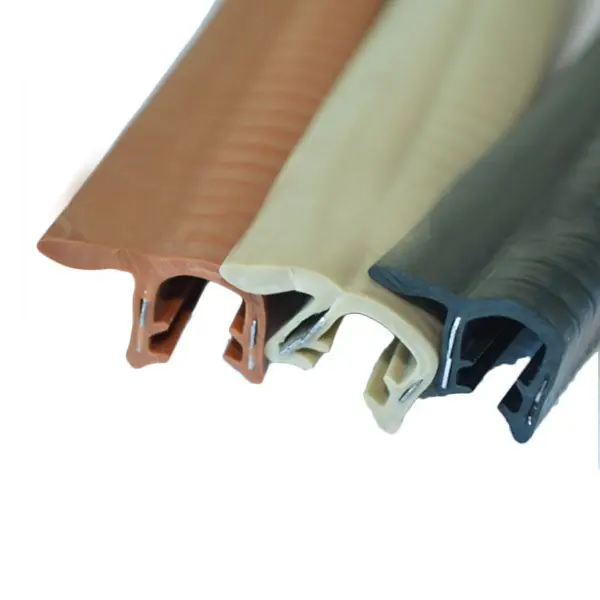

Material: PVC TPE TPV

Color: Grey, Brown, Grey, Red, Black, any other colour is available

Tensile strength: GT10MPA

Tolerance:+/- 1-5mm

Description: Mould extrusion, salt ,vulcanization,cooling

Customize: Avaliable ,as to technical drawing or actual sample

Temperature Range: EPDM -40 °F – 248 °F (-40°C – 120°C)

PVC -20 °F – 150 °F (-29°C – 65.5°C)

Silicone -60-220 centigrade

Hardness (Shore A):PVC :85 Durometer (Shore A)

Silicone/EPDM :70 Durometer (Shore A)

Feature

Excellent material performance: TPE combines rubber elasticity with plastic machining, TPV provides outstanding weather resistance, and PVC offers an economical, practical solution suitable for automotive weather strips and extruded rubber sealing strips.

Professional automotive standard: produced strictly according to the standards of the automotive industry with tensile strength exceeding 10 mpa, ideal for custom rubber seals, ensuring the stability of shape during long-term use.

Precision manufacturing: Molded extrusion with salt-bath vulcanization stabilizes the molecular structure and extends product lifespan, compatible with EPDM glass seal applications.

Wide temperature range: the EPDM materials can withstand from -40°C – 120°C, maintaining reliable hermetic performance in extreme climates.

Precise size control: product tolerances are strictly maintained within + -5 mm to ensure an ideal approach to the metal components of the car door.

Solution

For general sealing problems in the automotive industry, we offer professional solutions for car weather strips, individual rubber sealing and extruded rubber sealing. Ageing and cracks are solved by optimized vulcanization, installation difficulties are solved by precise size control, and noise problems are mitigated by specialized surface treatment. In addition, we can recommend the most suitable material and hardness combinations based on vehicle specifications to ensure optimal hermetic performance and user experience.