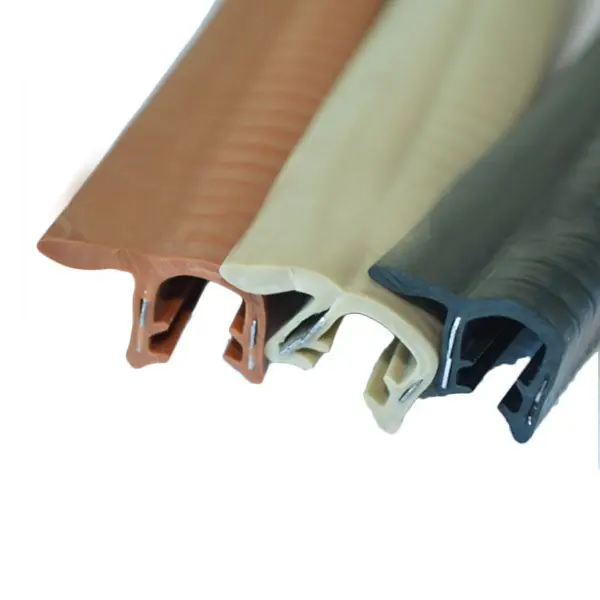

Material: PVC TPE TPV

Color: Grey, Brown, Grey, Red, Black, any other colour is available

Tensile strength: GT10MPA

Tolerance:+/- 1-5mm

Description: Mould extrusion, salt ,vulcanization,cooling

Customize: Avaliable ,as to technical drawing or actual sample

Temperature Range: EPDM -40 °F – 248 °F (-40°C – 120°C)

PVC -20 °F – 150 °F (-29°C – 65.5°C)

Silicone -60-220 centigrade

Hardness (Shore A):PVC :85 Durometer (Shore A)

Silicone/EPDM :70 Durometer (Shore A)

Application

Fixed glasses, play the role of shock-proof, waterproof, sealed

Feature

Several material options: PVC, TPE and TPA, each offering unique temperature adaptability and physical properties, making them ideal for passing glass TPE channels and sealed door glass profiles.

Exact production: adhesive extrusion combined with volcanization and salt bath cooling provides a tight structure and stable performance suitable for the application of extruded rubber sealing strips.

Wide temperature range: EPDM (-40°C – 120°C), PVC (-29°C – 65.5°C) and silicone (-60°C to 220°C) can meet various extreme conditions, compatible with road weather bands and EPDM glass seals.

Configuration: full-scale configuration is available on the basis of technical drawings or physical samples, including the size, color and cross-section design.

Precise size control: product tolerances are strictly maintained within + -5 mm to ensure accurate conformity and effective sealing during installation.Excellent tightness: a wide range of materials and precise dimensions provide optimal air, water and sound insulation for applications such as TPE glass channels, door glass profiles, extruded rubber tightness bands, car weather bands and epdm tightness glazing.