Rubber seals are essential components across various industries — from cars, homes, and apartments to ships and aircraft. They seal gaps in doors, windows, cabinets, and enclosures, effectively blocking noise, dust, and moisture.

One of the most versatile and reliable types of rubber seals is dual durometer rubber extrusion. In this article, we will explore what makes dual durometer rubber unique, its advantages, and why it’s an excellent choice for many projects.

What Is Durometer in Elastomer Hardness?

In simple terms, durometer measures how hard or soft a rubber material is — specifically, its resistance to indentation.

A durometer device, equipped with a calibrated gauge and an indenter point, presses into the rubber to measure its hardness. The result is recorded on a 0–100 scale:

- Higher numbers indicate harder, stiffer materials.

- Lower numbers represent softer, more flexible rubbers.

Understanding durometer values is essential to ensuring the material meets the performance and quality requirements of your application.

Understanding Rubber Shore Hardness

Rubber hardness is often specified using the Shore hardness scale. Selecting the correct hardness is crucial to achieving optimal sealing performance.

For example, EPDM 60A rubber:

- EPDM stands for Ethylene Propylene Diene Monomer, a material known for outstanding weather resistance.

- 60A indicates the hardness on the Shore A scale, suggesting a moderately firm rubber suitable for seals and gaskets.

Remember:

- A higher number = a harder material.

- A lower number = a softer material.

What Is Dual Durometer Rubber?

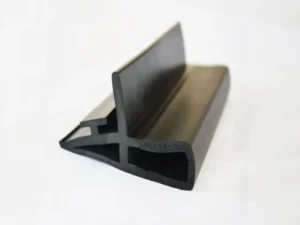

Dual durometer rubber extrusion combines two rubber materials with different hardness levels into one continuous profile.

Typically:

- The soft portion provides sealing, cushioning, and flexibility.

- The rigid portion delivers structural support and ensures firm attachment.

This combination is achieved through a process called co-extrusion, where both materials are simultaneously pushed through a specially designed die.

Why Is Dual Durometer Rubber So Reliable?

Dual durometer rubber offers several important advantages:

1. Enhanced Sealing Performance

The soft component conforms to surfaces for an excellent seal, while the rigid part maintains secure attachment — critical for demanding environments.

2. Improved Durability

Rigid bases protect the seal from mechanical stress, enhancing overall lifespan and resistance to wear and tear.

3. Greater Versatility

Available in a variety of designs and material combinations, dual durometer profiles can meet diverse application needs.

4. Cost-Effectiveness

By integrating soft and rigid elements into a single extrusion, manufacturing and installation costs are reduced without compromising performance.

5. Ease of Installation

Flexible yet structurally supportive, dual durometer profiles are easy to handle and install, saving both time and labor.

Types of Durometer Scales in Rubber Industries

There are 14 durometer scales, but the two most common in rubber manufacturing are:

- Shore A: for softer, flexible rubbers (seals, gaskets, flexible extrusions).

- Shore D: for harder rubbers and rigid plastics.

Selecting the right scale ensures accurate material performance for specific applications.

| Feature | Type A Scale | Type D Scale |

| Indentor Shape | Conical 35° | Conical 30° |

| Application | Suitable for softer rubbers and elastomers | Ideal for harder rubbers and plastics |

| Shore Hardness Range | 0 to 100 | 0 to 100 |

| Typical Material Range | Very soft to medium-hard rubber materials | Hard rubber materials, plastic, rigid elastomers |

| Indentor Tip Diameter | φ 0.79 | R 0.1 |

| Spring Load Value | 56.1 – 821.1 gf | 0 – 4533 gf |

| Test Method | ASTM D2240 | ASTM D2240 |

Popular Applications of Dual Durometer Rubber

Thanks to their unique properties, dual durometer rubber extrusions are widely used in:

| Industry | Application Example | Product Example |

| Automotive | Door and window seals | Automotive weatherstripping |

| Construction | Building facade seals | Glazing gaskets |

| Marine | Hatch covers, portholes | Marine edge trims |

| Aerospace | Cabin pressure seals | Aerospace gaskets |

| Consumer Goods | Appliance seals | Refrigerator door gaskets |

FAQ

Q: How do you test a rubber durometer?

A: Place the durometer perpendicular to the rubber surface. Apply steady pressure until the needle stabilizes, then read the hardness value. Multiple tests may ensure more accurate results.

Q: What is EPDM 60 Durometer?

A: It’s a durable black rubber made of EPDM and SBR, rated at 60 Shore A, ideal for outdoor use due to its weather and UV resistance.

Q: What is Shore A durometer?

A: A scale that measures the hardness of flexible materials. Lower numbers = softer; higher numbers = harder.

Q: What’s the difference between Shore A and Shore D hardness?

A: Shore A measures softer rubbers, while Shore D measures harder materials like rigid plastics.

Q: Is a higher durometer harder or softer?

A: Higher durometer values mean harder materials.

Q: What is the durometer range of silicone rubber?

A: Silicone rubber typically ranges from 30A (very soft) to 80A (fairly hard).

Conclusion

Understanding durometer hardness and the benefits of dual durometer rubber extrusion can make a huge difference when selecting materials for sealing, gasketing, or cushioning applications.

Dual durometer rubber delivers outstanding sealing, durability, and flexibility — all in one profile.

Are you ready to enhance your next project with custom dual durometer solutions?

Contact us today to discuss your requirements and explore how our expert team can help bring your ideas to life!